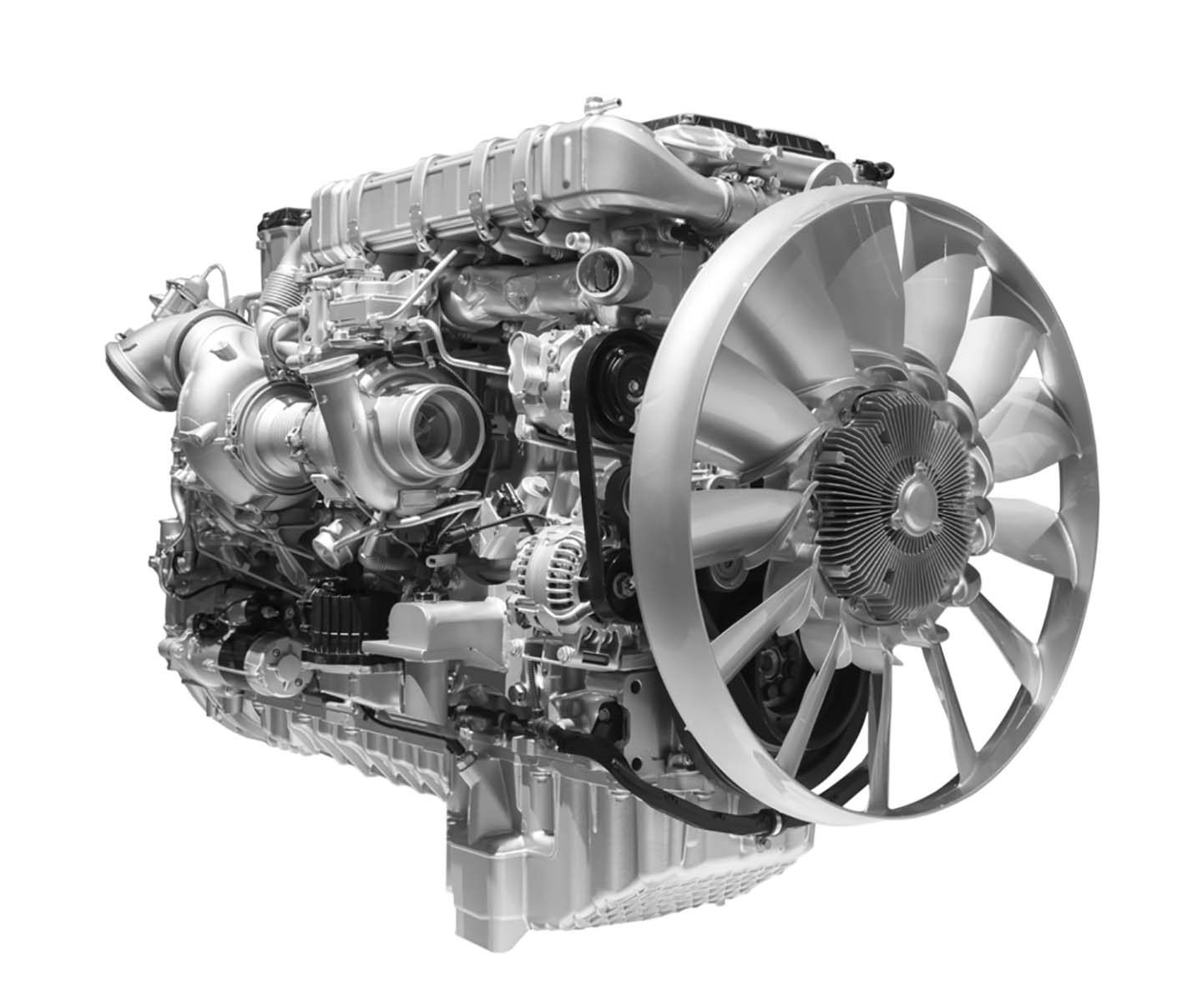

How Does a Turbocharger Work?

Mar 6th 2024

Philip Lange/shutterstock.com

Diesel engines run on highly compressed air and fuel. The turbocharger on a diesel engine increases airflow via compression so more can fit inside the combustion chamber. This produces more energy for faster acceleration, fewer emissions and better fuel efficiency.

According to GoMechanic, 98% of all diesel engines come with a turbocharger. This technology was first invented in the 1920s to increase power generation in diesel generators. However, it took over fifty years for the first turbocharged diesel passenger car to hit the market when Mercedes-Benz released the 300SD in 1978. So, how does a turbocharger work, and how does it affect vehicle performance?

Increasing Compression and Airflow with a Turbocharger

Naturally aspirated engines don’t compress air to burn fuel, limiting the output of gasoline vehicles. However, compression is an essential component in any diesel engine. It allows more fuel and air to combust by squeezing them into smaller spaces.

Diesel engines need to maintain an air-fuel ratio of 14.7-to-1 to generate power. The only way to increase the output is to force more air and fuel into the chamber. That’s where the turbocharger comes in. The engine induction stroke opens the intake valve, bringing in air. The piston then moves down to compress the air in the cylinder before injecting it into the combustion chamber. Once the air-fuel mixture burns, part of it gets rerouted through the exhaust gas recirculation (EGR) system instead of escaping out the exhaust. This air is cooled before moving through the turbo.

The recycled exhaust moving through the turbo spins the turbine wheel up to 150,000 rotations per minute (RPM). The turbine then powers the air compressor, bringing clean air through a vent. The clean air is pressurized up to 30% above normal atmospheric pressure, around 19 lbs. per square inch. The compressed air then flows into the combustion chamber, allowing the engine to burn more fuel per rotation. Using recycled exhaust gas to power the turbo contributes to turbo lag, or the amount of time it takes you to feel the boost after pressing the throttle. What is turbo lag?The lag comes from the engine having to generate exhaust gas to power the turbo, which can take several seconds or more at low RPMs.

Discover All of Our Turbocharger Parts

J. Lekavicius/shutterstock.com

Different Types of Turbos

Turbochargers come in various sizes and styles depending on the engine, but they all need to regulate the amount of air based on how much fuel goes into the combustion chamber. If there is too much fuel, it won’t burn all the way through, spreading debris and residue throughout the engine. On the other hand, if there isn’t enough air in the chamber, it will run lean, causing the engine to overheat while increasing harmful emissions.

Variable geometry turbos (VGTs) will adjust the path of the turbine based on flow and air pressure. They must be able to divert all the air they consume. Meanwhile, fixed geometry turbos use turbo actuators, or wastegate actuators, to eliminate excess air. The actuator acts as a pressure relief valve with a spring and a diaphragm. Once the pressure exceeds the allotted psi, the spring will force the diaphragm to open, allowing excess air to escape.

VGTs provide added flexibility and are generally more reliable than fixed geometry turbos. Both styles come with strict boost limitations and will siphon off excess air to maintain the ratio. If you want to increase the output of your engine, you need to swap out the turbocharger for a larger one that can handle more airflow. You also need to replace the turbo actuator to ensure it opens at the right time.

Comedstock/shutterstock.com

Turbocharger Problems and How to Solve Them

A lack of oil will damage the turbo. The oil lubricates the shaft and turbo housing to prevent metal parts from scraping against each other. It also dissipates the heat from the incoming exhaust to keep these components intact. If there is any debris caught in the oil or exhaust gas, it will clog the turbine housing, blocking the flow of air.

The actuator can also break down over time. The spring can become more susceptible to pressure, causing it to open sooner than it should, reducing the boost. The diaphragm may also fail to open if it gets stuck, trapping excess pressure inside the turbine, which could damage the housing and wheel. If your turbo isn’t responding or the lag gets worse, there could also be a problem with the sensors that regulate air pressure.

A broken turbo doesn’t just limit your ability to accelerate. It can also reduce fuel efficiency and increase harmful emissions by offsetting the fuel-air ratio inside the combustion chamber. Inspect the turbo for damage after periods of intense hauling and acceleration, and shop for turbo components to replace damaged parts before the problem gets worse.