What is an IPR Valve?

Oct 8th 2021

Diesel engines use high-pressure air and fuel to generate power unlike gas-powered vehicles, which use spark plugs to ignite air and fuel. Maintaining this pressure is a marvel of modern engineering. The engine pressurizes the fuel before injecting it directly into the combustion chamber. But the pressure must be exact, or the engine may lose power or fail to start altogether. So, how do diesel trucks maintain this delicate balancing act?

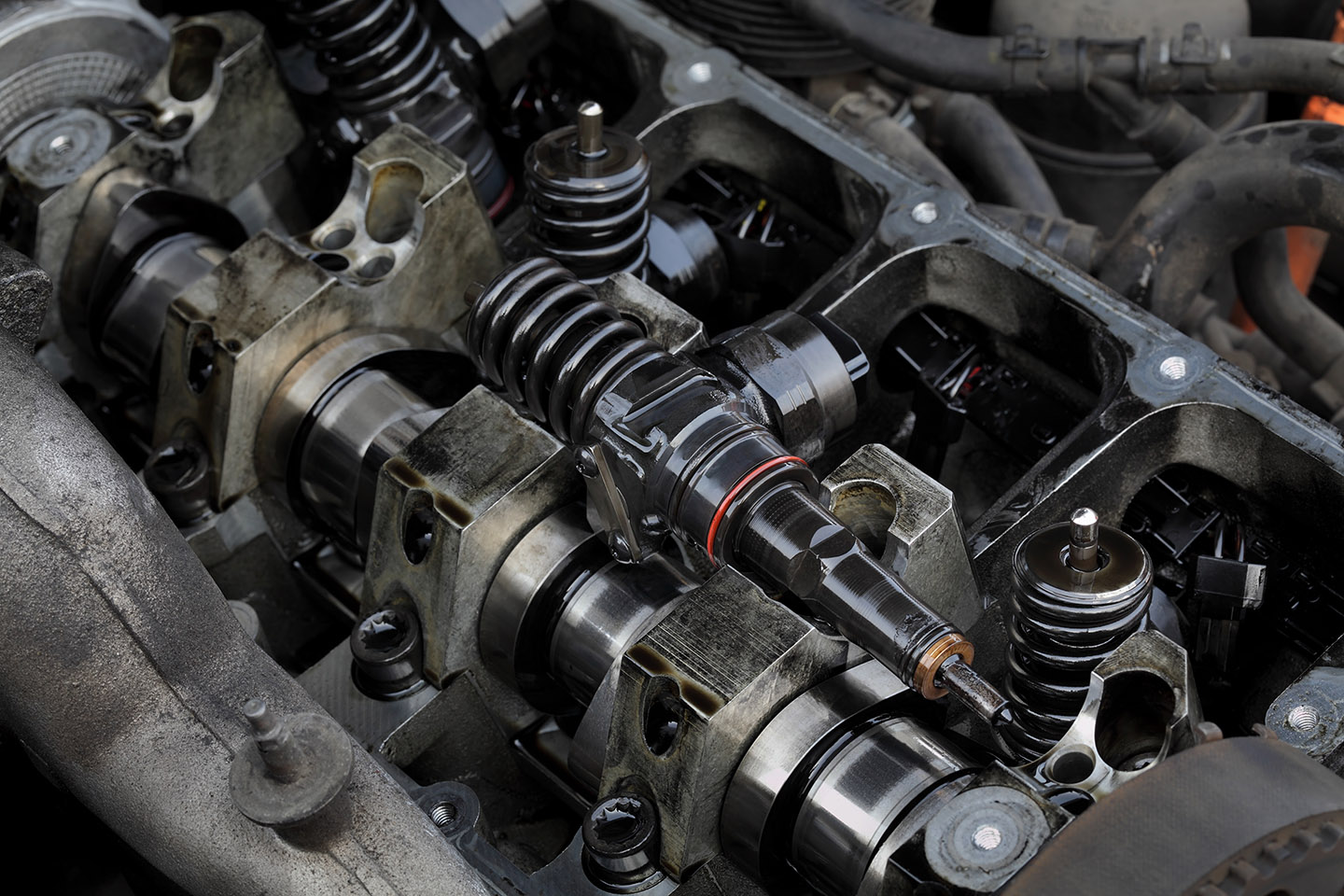

The engine needs a steady flow of high-pressure oil to operate the fuel injectors. That’s where the IPR valve comes into play. IPR stands for injection pressure regulator. The IPR valve controls the pressure of the oil being circulated throughout the engine. Engine oil is crucial for lubrication, and the valve is here to make sure the oil gets where it needs to go by controlling the flow. The IPR valve is a crucial component of the Powerstroke engine. Without enough oil, the fuel injectors would fail to fire, depriving the engine of fuel.

These devices are designed to last the test of time, but problems can still arise from time to time, especially if the high pressure oil pump is faulty. It can also become sticky. The O ring can also blow, which will result in all kinds of problems under the hood.

Learn more about IPR valves and what to do if you thinkyour IPR valve may be damaged.

What Does an IPR Valve Do?

Only Ford Powerstroke diesel engines are known for using IPR valves. Essentially, the injection pressure regulator valve maintains proper oil pressure in the high pressure oil pump (HPOP), usually between 3,000 and 4,000 PSI when the vehicle is running. This will drop down to around 500 PSI when idling. If the oil isn’t under enough pressure, the fuel injectors will fail to fire, which means the engine won’t start.

The high pressure oil pump also sends oil to other parts of the engine. It can help supply hydraulic fluid to actuators and help increase tension on timing belts and variable valve timing systems. Oil helps the entire engine run smoothly, and the IPR valve helps the high pressure oil pump do its job by controlling the flow of oil.

How Does the IPR Valve Work?

The valve is a surprisingly complex piece of machinery.

Pressure control in the engine system works as a closed loop. The IPR valve is just one piece of the puzzle. It works in tandem with the injection control pressure (ICP) sensor and the powertrain control module (PCM).

The IPR valve consists of two parts, a pilot operated valve and an electromagnetic actuator. It’s mounted on the back of the high pressure oil pump and regulates injection control pressure by discharging excess oil through a shuttle valve into the front cover and back to sump. It operates at different pulse widths. It is modulated from a duty cycle of 8 to 50%, which toggles injection pressure from 500 – 3,000 PSI.

For its part, the PCM controls the IPR valve using an internal ground switch. It’s preprogrammed to adjust injection pressure based on calibration to keep the engine running at peak efficiency.

Meanwhile, the ICP sensor is mounted on the left cylinder head. It provides feedback on the injector pressure system. It converts pressure into a 0- to 5-volt analog signal that the PCM uses to determine injection control pressure. The operating range is typically 0.7 to 3.2 volts.

Shop for New IPR Valves Today!

Why Does the IPR Valve Fail?

There are several reasons why your IPR valve might be malfunctioning. The three biggest culprits are:

Debris in the pilot valve: the pilot valve may get sticky over time as oil and other debris stick to the inside. You can use a screwdriver and some solvent or compressed air to clean off the pilot valve.

Debris in the actuator piston area: The piston area can also get dirty. To clean the actuator body and piston area, break down the valve and lubricate the parts with a solvent. Start assembling the valve but don’t tighten. The piston should move freely if it’s properly lubricated.

Damaged O Ring: The O ring prevents oil from escaping or leaking into the engine. Inspect the ring for damage and wear. If it appears broken or corroded, you’ll need a replacement O ring. There should also be a backup ring near the actuator as a second line of defense.

What Happens When the IPR Valve Fails?

If there is something wrong with your IPR valve, the oil won’t circulate properly throughout the engine. This can damage many different components as metal parts rub against each other, leading to a blown seal or gasket. A lack of oil can be devastating for the turbocharger, which will start to crack without enough lubrication. The fuel injectors will also fail or struggle to fire, causing the engine to suddenly lose power. You can drive with a bad IPR valve, but you risk damaging the entire engine, leading to an expensive rebuild.

Watch out for loud grinding noises, a sudden loss of power, misfires, and hard starts. There could also be a problem with the oil cooler, which cools off the oil before redistributing throughout the engine. If the oil is too hot, it will lose its lubricating properties. Check the fuel filter as well to make sure the injectors are using clean fuel. Excess carbon and soot can prevent the injectors from firing.

You’ll need to repair or replace a broken IPR valve as soon as possible, considering a faulty IPR valve can permanently damage your engine and injection control system. Check the OEM warranty to see if it is still valid.

Test the IPR valve before replacing it with a new one just to make sure. If it’s broken, shop for new 6.0 IPR valves based on your make and model. If you need to replace the valve, find a quality replacement part manufacturer, such as Motorcraft.

Use caution when replacing the valve yourself. When reassembling your valve, make sure the nut is not loose, or your next ride will be rough.

If it falls out of place, it might seem like you’ve got multiple bad injectors. Check the IPR nut for tightness after a few hours of use.

Every part and component needs to work intandem to produce enough pressure. And these parts can’t do their job without oil. A bad connection, build up of carbon, or blown O-ring can easily leave the entire engine starved for oil. Keep these tips in mind as you inspect your IPR valve. Maintain your engine parts to make the most of your time on the road. Stock up on diesel parts for peak efficiency.

Image Credits:

sima/Shutterstock.com

Patcharawadee Chaokruea/Shutterstock.com

CEPTAP/Shutterstock.com