6.0 Powerstroke HPOP Guide: What You Need to Know Before Replacing

May 20th 2025

Table of Contents

- How the 6.0 Powerstroke HPOP Works (and Why It’s So Important)

- Common 6.0 HPOP Failure Points (Compared to the 7.3)

- Symptoms and Diagnosis of a Failing HPOP on a 6.0 Powerstroke

- Repair vs. Replacement: Should You Fix Your HPOP or Replace It?

- 6.0 Powerstroke HPOP Replacement: Step-by-Step Best Practices

- Frequently Asked Questions (FAQ) about 6.0 Powerstroke HPOPs

If you own a 6.0 Powerstroke, you’ve probably heard of the HPOP, the High-Pressure Oil Pump, and its reputation. This critical pump is the heart of the 6.0L’s HEUI fuel injection system. When it has issues, your truck will let you know.

In this guide, we’ll break down how the HPOP works on a 6.0 Power Stroke, why it’s infamous, especially compared to the trusty 7.3’s HPOP, how to diagnose common failure symptoms, and what to consider before repairing or replacing it. We’ll also walk through best practices for HPOP replacement and answer frequently asked questions, including upgrade options and parts tips, with quality components from Bostech Auto. By the end, you’ll have a clear game plan for tackling 6.0 Powerstroke HPOP problems with confidence, DIY diesel owner style. Let’s get started!

How the 6.0 Powerstroke HPOP Works (and Why It’s So Important)

The 6.0 Power Stroke engine uses a High-Pressure Oil Pump (HPOP) as part of its HEUI (Hydraulic Electronic Unit Injection) fuel system. Unlike a traditional fuel injection pump, the HPOP doesn’t pressurize fuel; it pressurizes engine oil. Here’s a simplified rundown of how it works:

Oil Supply and Pressurization: The HPOP is mounted in the engine valley at the rear of the engine and is driven by the camshaft gear. Engine oil is supplied to the HPOP from a dedicated high-pressure oil reservoir on top of the engine block. The low-pressure oil pump (LPOP) draws oil from the pan, sending it through the oil cooler and filter into this high-pressure reservoir. The HPOP then takes that oil and pressurizes it to extremely high levels, upwards of 3,000 psi or more under demand.

Feeding the Injectors: The high-pressure oil output from the HPOP is fed into oil rails in the cylinder heads (one rail per head in the 6.0L). From these oil rails, the pressurized oil enters each fuel injector. Inside each injector, that oil pressure is used to amplify fuel pressure and trigger injection. In essence, the HPOP provides the muscle that allows the injectors to fire fuel into the cylinders.

Controlled by the PCM: An electronic Injection Pressure Regulator (IPR) valve, mounted on the HPOP, and an Injection Control Pressure (ICP) sensor work together with the Powertrain Control Module to regulate oil pressure. The IPR opens or closes to modulate pressure, and the ICP sensor reports the actual oil pressure in the rails to the PCM. This feedback loop ensures the right oil pressure is available for the engine’s needs, for example, higher pressure under heavy acceleration and lower at idle.

Why is the HPOP so important? Without sufficient high oil pressure, the injectors won’t fire properly. In fact, the 6.0 Powerstroke typically needs a minimum of about 500 psi of injection oil pressure to even start. If the HPOP can’t build pressure or if there’s a leak in the high-pressure oil system, you’ll get hard starts, misfires, or a no-start condition. In short, the HPOP is absolutely critical to your 6.0’s operation, which is why any HPOP issues need prompt attention.

Common 6.0 HPOP Failure Points (Compared to the 7.3)

The 6.0L Powerstroke HPOP has earned a bit of a bad reputation among diesel folks, especially when compared to its predecessor in the 7.3L Powerstroke. The 7.3’s high-pressure oil pump was relatively simple and robust; most 7.3 HPOPs last a long time and usually only struggle if pushed beyond stock power or very high mileage. In contrast, the 6.0 introduced some new designs and components that, while innovative, became common failure points. Let’s break down the key issues, with relevant products from Bostech Auto:

- Two Styles of 6.0L Power Stroke HPOP: The early round-body pump was used in 2003 and 2004. The later “square” pump was used from 2005 onward.

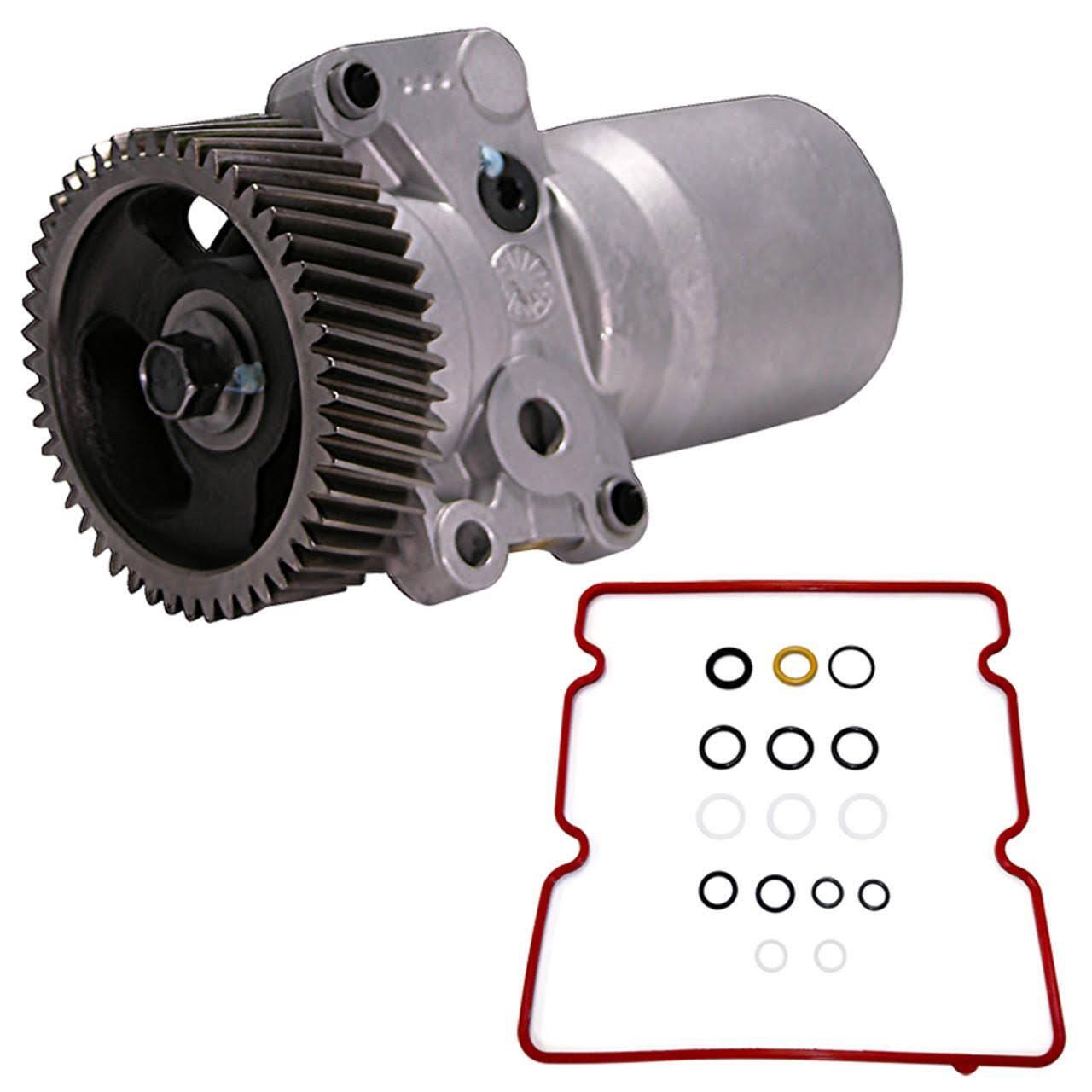

- Early 6.0 HPOP Design (2003 and 2004): Early-build 6.0s, generally 2003 and early 2004 model years, came with an aluminum-bodied, swash-plate style HPOP. Unfortunately, this design proved to be a weak link; these pumps are known to fail often. When they fail, they typically can’t maintain the necessary oil pressure, especially under load or when hot. If you have an early 6.0 (one easy clue is the ICP sensor location at the back of the engine under the turbo on 2003 and 2004 engines), be aware that its HPOP is a frequent culprit for hard start or no-start issues. Ford even updated the HPOP design mid-cycle because of how problematic the early pumps were. For replacements, Bostech offers a remanufactured HPOP for 2003–2004 6.0L PowerStroke, designed with upgraded internals for durability.

- Later 6.0 HPOP Design (2005 to 2007): In late 2004, for the 2005 model year, Ford introduced a new HPOP design. This later pump has a cast-iron body with a “V4” piston-style configuration. The good news: the later 6.0 HPOP itself is far more reliable and rarely fails internally. The bad news: it came with a new troublemaker, the STC fitting. The HPOP’s outlet on 2005 and later engines uses a Snap-to-Connect (STC) quick-connect fitting to join the pump to the oil supply branch tube. That STC fitting is notorious for blowing apart or leaking. A failing STC fitting produces symptoms just like a failing pump since either way you’re losing oil pressure. In fact, the STC fitting coming apart is one of the most common no-start causes on a 2005 to 2007 6.0. Ford later released an upgraded one-piece solid fitting to replace the problematic snap-connect. Bostech’s STC fitting update kit eliminates this issue.

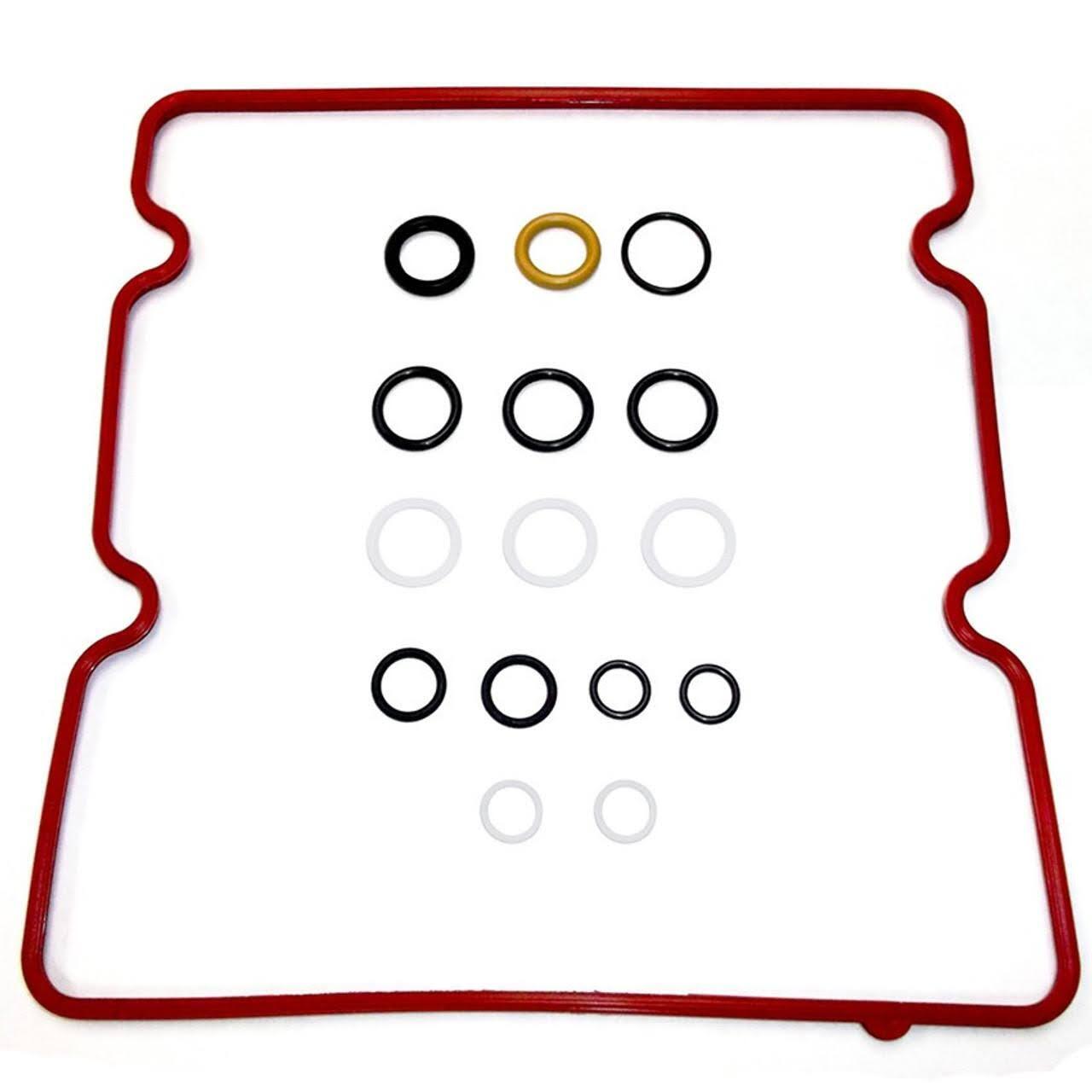

- Standpipes and Dummy Plugs: Apart from the pump itself, the 6.0’s high-pressure oil delivery system had other failure points. In 2004.5 and later engines, Ford used two-piece standpipes, which feed oil from the branch tube into the oil rails, and screw-in dummy plugs in the oil rails. The O-rings on these standpipes and plugs are known to flatten or tear over time, causing high-pressure oil leaks. A leaking standpipe O-ring often shows up as hard start when hot (long crank times) and eventually no-start. Updated standpipes and dummy plugs with improved O-rings are available; the updated ones can be identified by a different head size, such as 12mm hex vs 10mm on old style. Bostech’s standpipe and dummy plug kit provides these upgraded components for 2004.5–2007 models.

- IPR Valve Issues: The Injection Pressure Regulator (IPR) valve is the component that actually controls high oil pressure by bleeding off excess pressure. If the IPR fails or its screen gets clogged with debris, it can mimic HPOP failure symptoms. The IPR on the 6.0 can stick or the screen, which filters the high-pressure oil entering it, can rupture. Sometimes pieces of a failing HPOP or other debris end up on this screen. A bad IPR might cause low injection pressure and no start even if the pump itself is okay. Bostech’s IPR valve for 6.0L PowerStroke ensures reliable pressure control and is recommended during HPOP work.

- ICP Sensor Failures: The Injection Control Pressure (ICP) sensor measures the high oil pressure in the system. On 2003 to early 2004 engines, this sensor sits on the HPOP cover at the rear of the engine, where it gets cooked by heat; these early ICP sensors often fail, sometimes even leaking oil through the sensor. A bad ICP sensor can send incorrect pressure readings to the PCM, resulting in poor performance or no start, and may throw codes like P2285 for low ICP sensor circuit. In mid-2004, Ford relocated the ICP sensor to the front of the engine (passenger-side valve cover area) to improve its longevity. Bostech’s ICP sensor for the 6.0L PowerStroke is a reliable replacement for early models. A quick test for a bad ICP is to unplug it; the PCM defaults to a preset pressure, and if the engine starts, the sensor or wiring may be faulty.

- Comparison to the 7.3 HPOP: The older 7.3 Powerstroke’s HPOP was a different animal. The 7.3 used a gear-driven twin-plunger pump mounted at the front of the engine valley and had external high-pressure oil lines feeding the heads. It lacked things like an STC fitting or standpipes. Generally, the 7.3’s HPOP is very robust; failures were relatively rare, and leaks were usually due to worn O-rings or the external lines. Many 7.3 owners never touch their HPOP for the life of the truck unless they modify the engine for high horsepower, in which case upgrade pumps are available. In contrast, 6.0 owners have come to expect HPOP system issues at some point. The 6.0 simply has more potential failure points in its high-pressure oil system. The trade-off is that the 6.0’s injection system can respond faster and make more power stock-for-stock, but when something goes wrong, it’s often the HPOP or its fittings. The bottom line: the 7.3’s HPOP is bulletproof, the 6.0’s is, well, finicky.

Symptoms and Diagnosis of a Failing HPOP on a 6.0 Powerstroke

How do you know if your 6.0 Powerstroke HPOP or its related components are failing? The symptoms can range from subtle to a full-blown no-start, but they usually center around the engine struggling to achieve proper injection pressure. Here are the most common signs and some diagnostic tips:

- Hard Starts (Especially When Hot): One classic symptom is the truck becoming hard to start when the engine is warmed up. You might notice the engine cranks longer than normal before firing, or it may not start at all on a hot restart but will start again once cooled down. This often points to a high-pressure oil leak, like a standpipe/dummy plug O-ring leaking, or a weak HPOP that can’t keep up when the oil is thin and hot. Essentially, when oil gets hot and thinner, a marginal HPOP or a small O-ring leak may fail to build the required 500+ psi to fire the injectors. Cold starts might be okay, but hot starts fail; that’s a big red flag for HPOP system issues.

- No-Start Condition: If the HPOP or a critical fitting completely fails, the engine may not start at all, hot or cold. For example, when an STC fitting on a late 6.0 blows out, it often causes a sudden no-start. You might have been driving and the truck abruptly died, or you shut it off and it refused to restart. In these cases, the starter will crank and crank, but the engine won’t catch because injection control pressure isn’t reaching the minimum needed. A confirmed no-start due to low injection pressure will usually be accompanied by 0 psi reading on ICP if you can monitor it or extremely low (~100 psi) while cranking, and possibly a check engine light.

- Check Engine Light & Codes: Speaking of lights, a failing HPOP system often triggers diagnostic trouble codes. Common codes include P2284, P2285, P2286 relating to the ICP sensor circuit and P2290 or P2291 which specifically indicate “Injector Control Pressure Too Low.” For instance, P2290 means ICP is low under load, and P2291 means ICP did not build enough during cranking. If you pull codes and see P2290/P2291, you’re definitely looking at a high-pressure oil problem. Always scan for codes if you suspect HPOP issues; they can strongly point you in the right direction.

- Rough Running, Miss, or Stall: In some cases, an HPOP that’s failing gradually might cause general poor performance. You could get a rough idle, a “miss” or stumble under acceleration, or even stalling at stoplights. These symptoms overlap with fuel delivery issues, but if fuel checks out, think high-pressure oil. Inadequate injection pressure can cause one or more injectors to not fire consistently. A telltale scenario is a hot engine that suddenly stalls while driving or at idle and then won’t restart until cooled. That often means the HPOP couldn’t maintain pressure and the engine died due to essentially fuel starvation since the injectors stopped firing.

-

- ICP Readings and IPR Duty Cycle (Advanced Diagnostics): If you have access to a scan tool that can read live data, such as Ford IDS, ScanGauge, or Torque app with appropriate PIDs, take a look at ICP (psi) and IPR (%) while cranking or running. During cranking, watch the ICP pressure: as mentioned, it needs to hit around 500 psi to start. If it’s not reaching that, you have an HPOP system issue. Simultaneously, see what the IPR duty cycle is doing. The IPR is commanded by the PCM; a normal cranking IPR % might climb to, say, 30-40%. If the PCM maxes out the IPR (85% is effectively “full demand”) and you still see low ICP, that confirms the high-pressure system can’t build pressure. On a running engine, an IPR that’s constantly extremely high, near 60-85% at idle or light throttle, indicates the pump is struggling to meet desired pressure, which could be a leak or weak pump. In summary, high IPR % + low ICP psi = HPOP or leak problem. Using these readings can help distinguish between a bad sensor, such as ICP reading nonsense, and a true pressure issue.

- Air Test for Leaks: Many diesel techs perform an “air test” on the high-pressure oil system to pinpoint leaks. This involves supplying shop air, around 100 psi, into the HPOP system, often via the ICP sensor port or a test adapter on the IPR, with the IPR commanded closed. By listening for escaping air, you can identify where the leak is: for example, air hissing loudly in the valve cover area might mean leaking standpipe O-rings; air from the rear of engine might mean a blown STC fitting; air in the crankcase could mean injector seal failure. This is a more advanced diagnostic step, but it’s good to know that if initial tests point to a high-pressure leak, an air test can pinpoint the exact source before you yank the pump. If you’re a DIYer without specialized tools, you might skip this, but a professional shop will likely do an air test as part of diagnosing an HPOP complaint.

- Other Checks: Always verify the basics too; ensure your engine oil level is correct (low oil level can cause HPOP starvation), and that the low-pressure oil system is functional (the HPOP can’t work if the feed from the LPOP is compromised). These are usually fine, but it’s wise to rule out a simple low oil or weak LPOP before diving into HPOP surgery. Also, if your engine is a 2003-2004, check for oil in the ICP sensor connector, a sign of ICP sensor failure; replace the sensor with Bostech’s ICP sensor if so and recheck performance. For any year, inspect the IPR valve: you can remove the IPR and look at its screen for debris or damage. A torn IPR screen or metal shavings on it mean internal failure upstream, likely the HPOP itself shedding metal. A clean IPR doesn’t 100% mean the HPOP is good, but a dirty/damaged IPR certainly gives clues, and you’d at least replace the IPR with Bostech’s IPR valve in that case.

By systematically observing these symptoms and using the right diagnostic steps, you can narrow down whether your 6.0’s issues are truly the HPOP or its fittings, or something else like fuel, FICM, etc. This is important because the HPOP is buried and not cheap; you don’t want to replace it unnecessarily. Once you’re confident the HPOP system is at fault, it’s decision time: repair or replace? Let’s discuss that next.

Repair vs. Replacement: Should You Fix Your HPOP or Replace It?

When faced with a high-pressure oil system problem on the 6.0, a big question is whether you can repair the issue with simpler fixes or if you need to outright replace the HPOP. The answer depends on exactly what failed. Here are some scenarios and advice to help you decide:

- STC Fitting Failures (2005 to 2007): If your truck is a 2005 to 2007 model and the only issue is the STC fitting, for example, it blew apart, or you’ve diagnosed a leak at that connection, you’re in luck; this can be repaired relatively inexpensively. Ford’s updated STC fitting kit replaces the snap-to-connect coupler with a solid threaded connector. Bostech’s STC fitting update kit solves the problem permanently. The procedure still requires getting to the pump, meaning you have to remove the turbo and HPOP cover, but you don’t necessarily need to replace the pump itself. Many late 6.0 HPOPs go on to live long lives after an STC fix. So if your pump was performing fine and you find the STC was the culprit, you can replace the fitting and any related seals and call it a day. Pro tip: While you’re in there, inspect the pump’s drive gear and housing for any damage; for instance, if the STC failed violently, sometimes the branch tube can whack the rear engine cover or pump. Such damage is rare, but if found, that might change the plan to pump replacement. In most cases though, STC fix equals back in business, with no new pump needed.

- Leaking O-Rings (Standpipes/Dummy Plugs): Similar to the STC scenario, if you determine that standpipe or dummy plug O-rings are leaking, you can usually fix that without replacing the HPOP. Updated standpipe and plug kits are readily available and not very expensive. Bostech’s standpipe and dummy plug kit includes improved O-rings for 2004.5–2007 engines. The repair involves pulling the valve covers and oil rails to swap in new standpipes and plugs with fresh O-rings. Importantly, you might choose to do this in conjunction with other work. For example, if you’re already pulling the turbo and HPOP cover for an STC fitting, it’s a great idea to also pop off the oil rails and do the standpipes/plugs at the same time for 2005 and later engines. For 2003-2004 engines, they don’t have the same standpipe setup; instead, they have a J-tube and braided lines under the valve cover which rarely fail unless disturbed. In summary, O-rings are a wear item; replacing them is a repair that restores lost pressure. It’s wise to do this preventive repair on any high-mileage 6.0 when you have the chance, for example, during an HPOP replacement job, definitely put in new standpipes/plugs on a 2005 or later model.

- Failed Early HPOP (2003 to 2004 trucks): If you’ve got an early 6.0 and its swash-plate HPOP has internally failed, there is unfortunately no “easy fix” for that pump. Internal failures, like scored housings or cracked swash plates, mean the pump can’t build pressure. The only real solution is to replace the pump with a new or remanufactured unit. Bostech’s 2003–2004 6.0L HPOP is built to avoid original flaws. When doing so, it’s strongly recommended to replace the IPR valve at the same time or at least the IPR screen/o-rings, because a failing pump could have sent debris into the IPR. Bostech’s IPR valve is a smart addition to ensure reliability.

- Failed Late HPOP (2005 to 2007 trucks): It is relatively uncommon for the later piston-style HPOP to fail on its own, aside from the STC issue. But it can happen, especially if the pump was starved of oil or ran with contamination. If you have a late model and you’re positive the pump itself is bad, for example, you’ve ruled out STC, standpipes, IPR, etc., and still have low pressure, or you found metal shavings in the IPR which likely came from the pump, then pump replacement is necessary. Bostech’s 2004.5–2010 6.0L HPOP comes with the updated STC fitting. Just like with early pumps, do the IPR valve at the same time with Bostech’s IPR valve.

- Cost Considerations (Pump Replacement): Replacing the HPOP is one of the more labor-intensive fixes on a 6.0. It involves significant disassembly (see the next section for steps). If you’re paying a shop, the labor can be hefty; if you’re doing it yourself, it’s a big time investment. Therefore, you don’t want to do it twice. This is why the general consensus is: if you go in to replace the pump, address all related failure-prone parts in one go. That means: updated STC fitting with Bostech’s STC kit, new standpipes/dummy plugs with Bostech’s standpipe kit, new IPR with Bostech’s IPR valve, new ICP sensor with Bostech’s ICP sensor if yours is the old style or suspect, and fresh gaskets/O-rings everywhere. This shotgun approach ensures that once it’s all back together, you won’t have to tear it down again for one little $5 O-ring you neglected. It might add a bit of cost, but it’s worth it for peace of mind.

- Pros and Cons, Repair vs Replace: In summary, if the root cause is a minor part, fitting or seal, fix that part. If the pump itself is suspect or has known damage, replace the pump. The pros of repairing fittings/seals are cost savings and retaining your original pump if it was fine. The cons are that you might fix one leak only to have another weak spot show up later if you didn’t catch everything. The pros of full replacement are renewed reliability and often an upgraded design pump; cons are higher cost and more work. Sometimes owners will opt to replace the pump proactively if the truck is very high mileage and already torn down, even if the STC or O-rings were the immediate issue, simply because while you’re in there, might as well put a fresh pump in for the long term. This really depends on your budget and plans for the truck. If the existing pump has, say, 200k miles on it, you might choose to change it with Bostech’s HPOP. If it’s relatively low miles and looks good, maybe not.

- Quality of Replacement Parts: One more note: quality matters for these high-pressure oil system parts. Stick with OEM or reputable aftermarket suppliers for HPOP and related parts. The HPOP has to maintain extremely high pressure, and cheap no-name pumps or IPR valves have been known to fail quickly or not perform to spec. Bostech’s remanufactured pumps, for example, the 2003–2004 HPOP and 2005–2010 HPOP, are built to OEM specifications with new internal seals and are tested to ensure they meet the required pressure and volume. Going with a quality remanufactured HPOP can save money over OEM-new while still giving you reliability. The same goes for seal kits and fittings; use the updated Ford parts or quality equivalents from Bostech. In short, don’t cut corners on the HPOP system; you don’t want to do this job twice!

With the decision made to repair or replace, let’s assume you’re about to roll up your sleeves and replace the HPOP or at least remove it to fix something. In the next section, we’ll go through a step-by-step outline of how to replace the 6.0 HPOP, along with some tips to make the job go smoother.

6.0 Powerstroke HPOP Replacement: Step-by-Step Best Practices

Replacing the HPOP on a 6.0 Powerstroke is a significant job, but it’s doable for a dedicated DIY mechanic with the right tools and patience. The pump sits under the turbo at the rear of the engine valley, so a lot of the work is getting to it. Below is a high-level step-by-step guide. Always refer to a detailed repair manual or guide for torque specs and all precautions. If you’re not comfortable with any step, consult a professional.

1. Prep the Truck: Begin by ensuring the engine is cool to avoid burns. Disconnect the batteries for safety. It’s also a good idea to drain the engine coolant if you plan to remove the intake manifold or EGR cooler; some coolant connections will be opened in that process in 2005 and later trucks. Remove the air intake tubing going to the turbo and take off the engine dress cover if installed.

2. Remove the Turbocharger: The turbo has to come off to access the HPOP cover. Disconnect the charge air cooler (CAC) pipe from the turbo outlet, and disconnect the exhaust downpipe V-band clamp at the turbo. Remove the turbo oil feed line on top of the turbo and the oil drain tube below the turbo, two bolts into the block. Unplug the electronic vane control connector if 2005 or later with VGT control. Then remove the turbo mounting bolts. In the early 6.0s (2003), there was a two-piece turbo; later, a single VGT turbo; either way, unbolt it and carefully wiggle the turbo out of the engine bay. It’s heavy; take care lifting it out. Pro Tip: Stuff clean rags in any open pipes, intake Y, exhaust up-pipes, to prevent debris from falling in while you work.

3. Remove Intake Manifold/EGR Assembly (if needed): This step may not be strictly required in all cases, but many find it easier to remove the upper intake manifold and EGR cooler to gain more room. On 2005 to 2007 trucks, the EGR cooler runs along the top valley; unbolt it from the intake and exhaust manifold, and disconnect its coolant lines, then remove the cooler. Bostech’s EGR cooler for the 6.0L PowerStroke is a robust replacement if needed. Then remove the intake manifold, the aluminum piece under the EGR valve/throttle; it’s a few bolts and comes off, exposing the top of the engine valley and HPOP cover area. In 2003 to 2004 trucks, the EGR cooler setup is slightly different but you may still consider removing the intake plumbing for room. Removing these components gives a clearer view and access to the HPOP cover and the branch tube connections.

4. Unplug and Remove Sensors/Parts on HPOP Cover: Now you should see the rectangular HPOP cover at the rear valley. Before removing it, disconnect the wiring connectors for the ICP sensor if it’s on the HPOP cover in your year and the IPR valve, which is on the HPOP itself, accessible through the cover. The IPR valve has a 2-wire connector; unplug it. You will be removing the IPR along with the pump or you can take it out first with a special socket, your call. Also remove the glow plug control module or any brackets that may be bolted on top of the HPOP cover; it varies by year.

5. Remove the HPOP Cover: Remove the bolts securing the HPOP cover to the engine block; there are several small bolts around the perimeter. Be careful not to drop any bolts or debris. Gently pry up the cover; it may be sealed tightly with silicone or a gasket. Once it’s loose, lift it off and set it aside. Now you’ll see the HPOP sitting in the rear of the valley, likely with some oil still around.

6. Disconnect HPOP from Branch Tube: This part differs early vs late engines:

-

-

- For 2005 and later engines with the STC fitting: The pump’s output is connected via a stubby STC coupler to the branch tube. If the STC is intact, you’ll need to unclip or unbolt it per the updated kit instructions; Bostech’s STC fitting kit uses a bracket with bolts. If it’s the old style, it might simply pull apart as you remove the pump. Ensure the connection between pump and branch tube is free; you might have to remove a snap ring or bolt depending on what style is in there. If it already blew apart, you might find it already disconnected with pieces rattling around, so watch for that.

-

-

-

- For 2003 to 2004 engines: Instead of an STC, there is a rigid “J-tube” or pipe connecting the pump to the branch. You will have a bolt securing that tube’s flange. Remove the bolt and the flange to free the pump’s outlet from the branch tube.

-

7. Unbolt and Remove the HPOP: The HPOP itself is usually held by two or three bolts to the engine and possibly a bracket. Remove those bolts. Before pulling the pump out, be aware it meshes with the camshaft gear. On removal, it should slide out of the gear mesh; there’s no timing to worry about; the gears are not timing marks, it’s just a drive. Still, be gentle to not drop anything. You may have to wiggle the pump and pull straight back to disengage it from the gear. When it comes free, also watch for the pump drive gear or stub shaft; on some pumps the gear stays in the engine, on others it’s attached; just ensure nothing drops into the engine. Remove the old pump and set it on a rag. Expect some oil spillage.

8. Inspect and Swap Over Components: With the pump out, retrieve the old gasket if any from the engine surface; sometimes it sticks. Now’s the time to inspect the branch tube end; check if the O-rings or fitting are damaged. If you have the updated STC kit ready, install the new fitting on the pump or branch as directed by Bostech’s STC kit; some kits fix the fitting to the pump with bolts and a bracket to prevent future separation. If your replacement pump doesn’t include an IPR valve, swap your old IPR to the new pump: carefully unscrew the IPR from the old pump using the special deep socket; it’s like a 1-3/8” socket. Inspect the IPR screen; if it’s dirty or torn, strongly consider a new IPR valve with Bostech’s IPR valve. If you are installing a new IPR, put a little oil on its O-rings and install it into the new pump. Also double-check that the new pump has the required O-rings on its outlet and inlet if any in place. Some new pumps come with plastic caps protecting those O-rings; remove the caps and keep the O-rings clean.

9. Install the New (or Rebuilt) HPOP: Ensure the area is clean; no old gasket bits or dirt in the valley. If your pump uses a gasket or seal to the block, position the new gasket. Slide the new HPOP into position, aligning its drive gear with the cam gear. You may need to twist it slightly to get the gear teeth to mesh; do not force it. It should fully seat against the block when aligned. Once in, reinstall the pump mounting bolts and torque them to spec; typically these are small bolts, around 18 to 20 ft-lbs, but check your manual. Reconnect the pump to the branch tube: if STC, push the new fitting in place and secure it, for example, bolt the bracket if the update kit uses one. If J-tube style, reattach the tube’s flange and bolt. Make sure any new O-ring seals are lubricated with a bit of fresh oil and seat correctly; you want a good seal here to avoid leaks. Use Bostech’s 2003–2004 HPOP or 2004.5–2010 HPOP depending on your model year.

10. Reinstall HPOP Cover (with New Gasket): It’s crucial to prevent oil leaks, so use a new HPOP cover gasket or sealant as required. Many HPOP kits include a new cover gasket; the 2003 to 2004 use a gasket, later ones often use RTV silicone sealant. Clean the cover and mating surface on the block thoroughly. If using RTV, apply a thin bead as per Ford’s recommendation. Place the cover back on and tighten all the cover bolts evenly to spec, usually around 97 in-lbs for small bolts. Don’t overtighten and risk cracking the cover. Bostech’s installation kits often include necessary gaskets.

11. Reassemble Removed Components: Now reconnect the ICP sensor and IPR valve connectors. Reinstall any brackets or modules you removed. If you took off the intake manifold/EGR cooler, now reinstall those with new gaskets as needed. Bostech’s EGR cooler is a reliable option. Reconnect coolant lines to the EGR cooler and tighten the intake and EGR bolts to spec. Reinstall the turbocharger: replace the turbo pedestal O-rings, two on the bottom of the turbo feed/drain interface, to prevent leaks. Drop the turbo in, bolt it down, torque the mounting bolts, reattach the downpipe clamp, ensure it’s seated well to avoid exhaust leaks, and hook up the CAC charge pipe. Reconnect the turbo oil feed line on top with a new copper washer perhaps and bolt the oil drain tube back up. Plug in any sensors or connectors, vane actuator, etc. Reattach the air intake hose and filter assembly. Essentially, put everything back that you took off, double-checking all connections, fuel lines, sensors, etc., depending on how far you disassembled.

12. Refill Fluids and Double-Check: If you drained coolant, refill the coolant now. Also check your engine oil level; the HPOP reservoir should have refilled from the crankcase by now, but it wouldn’t hurt to verify oil is at the correct level. In some cases, people prefer to pre-fill the HPOP reservoir via the oil filter housing or a plug on top of the reservoir to shorten crank time, but it’s usually not necessary as the LPOP will fill it quickly on cranking.

13. Crank and Start the Engine: With everything back together, it's the moment of truth. Reconnect the batteries. Cycle the key a few times; this doesn’t directly fill the HPOP, but allows the fuel bowl to refill if it was drained during intake removal. Now crank the engine. Expect a longer crank than normal on the first start, because the high-pressure oil system has air in it that needs to be purged. It may take 10 to 15 seconds of cranking, sometimes two 10-second tries, for the oil pressure to build and the injectors to start firing. Once it starts, let it idle. Check your ICP pressure reading if possible; it should be normal, 500 to 700 psi at idle, roughly. The idle might be a bit rough for a few seconds up to a minute as any remaining air works its way out of the oil rails.

14. Inspect for Leaks and Final Checks: Immediately look around for any leaks. Key areas: around the HPOP cover, any oil seeping out, high-pressure fittings under the cover, you’d need to remove again to see, so hopefully all good there, turbo oil feed/return connections, oil leaks, fuel connections if any were disturbed, and coolant lines around EGR cooler. If something is leaking badly, shut down and address it. If all looks good, let the engine warm up and take it for a test drive. Monitor that the truck runs well under load. It should feel strong and not hesitate. A successfully replaced HPOP system should restore full injection control pressure, meaning your hard start or no-start issue should be gone.

15. Post-Repair Considerations: After a successful repair, change your engine oil and filter at the next convenient interval, especially if the old HPOP had a failure that could have contaminated the oil with metal. Clean oil is the lifeblood of the HPOP. Also, if not already done, consider adding an upgraded oil filtration or bypass filter kit; anything that keeps oil cleaner can help extend the life of your new HPOP and injectors. And keep note of the parts you updated, STC fitting, standpipes, etc., for your maintenance records; you’ve essentially bulletproofed that aspect of your 6.0.

Replacing a 6.0 HPOP is a big job, but with patience and attention to detail, you can successfully do it and enjoy a reliable high-pressure oil system again. Take your time, follow guides, and don’t hesitate to ask the online PowerStroke community for tips; many DIYers have done this and can share real-world advice. Now, let’s move on to some frequently asked questions regarding 6.0 HPOPs, upgrades, and related parts.

Frequently Asked Questions (FAQ) about 6.0 Powerstroke HPOPs

Q: What exactly does the HPOP do on a 6.0 Powerstroke?

A: The HPOP (High-Pressure Oil Pump) is responsible for creating the extremely high oil pressure required to actuate the fuel injectors in a 6.0L Power Stroke engine. Unlike a traditional fuel injection pump, it doesn’t pressurize fuel; it pressurizes oil, which then powers the injectors. Without the HPOP, the injectors can’t fire, and the engine won’t run.

Q: What are the symptoms of a failing HPOP on a 6.0?

A: Common symptoms include hard starting, especially when the engine is warm, very long cranking times before the engine starts, or a no-start condition where it cranks but doesn’t start. You might also experience rough running or stalling if the pump can’t maintain pressure. Often, there will be diagnostic trouble codes like P2290/P2291 for low ICP pressure or ICP sensor codes. If the failure is sudden, like the STC fitting blowing out, the truck may die while running and not restart. Essentially, any scenario where the engine isn’t getting the needed 500+ psi of injection control pressure will manifest as these symptoms. It’s a good idea to use a scan tool to confirm low ICP pressure if you suspect HPOP issues.

Q: My 6.0 has hard hot-start issues. Does that mean the HPOP is bad?

A: Hard hot-start, where the truck starts fine cold but struggles or won’t start after it’s warmed up, is a hallmark of high-pressure oil system leaks in the 6.0. It doesn’t necessarily mean the HPOP pump is bad; more often, it’s due to leaking seals, such as the standpipe/dummy plug O-rings or an STC fitting leak on 2005 and later models. When the oil is hot and thin, those leaks prevent building enough pressure. The pump could be perfectly fine but just unable to compensate for the leak. Of course, a weak pump could also show similar symptoms. The best approach is to diagnose properly: check hot cranking ICP pressure; if it’s low, then go in and inspect O-rings, STC, etc., before condemning the pump. In many cases, fixing the leaks with Bostech’s standpipe and dummy plug kit or STC fitting kit will solve hot-start issues without needing a new HPOP.

Q: Are 6.0 HPOPs interchangeable between years (2003 to 2007)?

A: Not directly, no; there were two different styles of HPOP on the 6.0, and they have different fitments. The 2003 to 2004 pump (“round” aluminum style) and the 2005 to 2007 pump (“square” cast iron style) are not a simple swap because the later one uses the STC fitting and different branch tube setup. However, with additional parts, some early-truck owners have retrofitted the 2005-style pump into 2003 to 2004 engines to gain its reliability. This isn’t a straightforward bolt-in; it would require the 2005 and later branch tube and STC fitting setup, and possibly a different front cover or adapter. Most people stick with the correct pump for their year range. Bostech offers 2003–2004 HPOP and 2005–2010 HPOP to match your build date. Always double-check your build date and VIN split when ordering an HPOP. When in doubt, consult a knowledgeable parts supplier or forum to ensure you get the right pump.

Q: Can I upgrade my 6.0 Powerstroke HPOP for better performance?

A: The stock HPOP is sufficient for stock injectors and mild tuning. Unlike the 7.3, where high-performance dual HPOP setups or “Adrenaline” pumps are common for big injectors, the 6.0’s HPOP generally isn’t the first limit for power; the fuel injectors and turbo become limitations sooner. That said, there are some upgraded or higher volume HPOPs available for the 6.0, mainly intended for those running larger-than-stock injectors or seeking every bit of ICP they can get. For instance, Bostech’s remanufactured HPOPs provide reliable pressure for most builds. For the average user, though, a new OEM or quality remanufactured HPOP and the proper updates (STC, etc.) is the best “upgrade”; it will restore lost performance. One more upgrade to mention: aftermarket HPOP gauges or ICP gauges are available so you can monitor your high-pressure oil system in real time. This can be useful if you’re frequently pushing your truck hard or want early warning of pressure drop.

Q: Should I replace the IPR or ICP sensor when I replace the HPOP?

A: It’s highly recommended to replace the IPR valve whenever you replace the HPOP. The IPR is critical to controlling the pressure and if it’s original, it’s likely worn or could have debris from the failing pump. Many HPOP failures involve metal bits that get caught in the IPR screen, so you don’t want to put a brand new pump in and then have a sticky IPR cause issues. Bostech’s IPR valve is a must. At the very least, install a new screen and O-rings on the IPR if the budget is tight, but ideally install a new IPR valve assembly for maximum reliability. As for the ICP sensor, consider its age and location: if you have a 2003 to early 2004, that sensor has been living in a hot oil bath for years; it’s wise to replace it while you have access, with the turbo/HPOP cover out, it’s much easier to get to. Bostech’s ICP sensor is ideal for early models. On 2005 and later trucks, the ICP sensor is up front and easy to change later, so it’s not necessary unless you know it’s faulty. In summary: IPR, yes replace in most cases; ICP, replace if it’s the old style or if you’ve had ICP-related codes or issues.

Q: How long does it take to replace a 6.0 HPOP?

A: For an experienced technician with all the right tools, the job might be done in around 6 to 8 hours; book time is often in that ballpark. For a DIY enthusiast doing it the first time, plan for a full weekend. There’s a lot that has to be removed and reinstalled, turbo, potentially intake, etc., and you want to go slow and careful, especially cleaning gasket surfaces and making sure all connections are correct. If you also do the standpipes, dummy plugs, and fitting upgrades during the job, add a bit more time. The first time is always the longest; some very skilled 6.0 techs can do it faster. The key is not rushing; missing a step or dropping a bolt can set you back, so methodical work pays off here.

Q: What is the “STC fitting update” I keep hearing about?

A: “STC” stands for Snap-To-Connect, referring to the quick-connect coupler used on late 6.0 HPOPs (2005 to 2007) to attach the pump’s output to the branch tube. The update is a retrofit kit that replaces this two-piece snap coupler with a one-piece solid fitting. The original STC fitting can flex and finally crack or pop apart, leading to sudden high-pressure oil loss. Bostech’s STC fitting update kit is robust and eliminates that failure mode. Ford issued a service bulletin for this, and most 6.0 owners or shops have done the update on any truck that hadn’t had it yet. If you’re unsure whether yours is updated, you can often tell by VIN lookup at a dealer, or by physically examining it, which unfortunately requires removal of the turbo and HPOP cover to see. If you’re doing any work in that area and it hasn’t been updated, do it now. It’s far cheaper to install the ~$50 STC update kit than to deal with a breakdown later.

Q: Where can I get quality replacement parts for the HPOP and high-pressure oil system?

A: There are many sources; you can go OEM Ford (Motorcraft parts) or reputable aftermarket. Bostech, for example, is a well-known aftermarket supplier that remanufactures diesel components. They offer remanufactured HPOPs for the 6.0 Powerstroke that meet OEM specs and come with new seals and gaskets, such as the 2003–2004 HPOP and 2004.5–2010 HPOP. You can find these pumps and related parts through diesel parts retailers or directly from Bostech’s Ford High-Pressure Oil Pump section. Make sure to buy from a trusted vendor; avoid ultra-cheap deals on auction sites as those often are inferior quality. It’s worth checking out Bostech’s catalog for the 6.0; they often bundle things like an HPOP replacement kit that includes the pump, the STC update, standpipe and dummy plug kit, gaskets, etc., which can be convenient. Additionally, ensure you get the correct pump for your year as noted earlier. Don’t forget to also grab an IPR valve with Bostech’s IPR valve and maybe an HPOP installation seal kit with cover gasket, branch tube O-rings, etc., if not included. Investing in quality parts now will save you headaches down the road.

Q: After replacing the HPOP, what else should I do to keep my 6.0 healthy?

A: Once your new or repaired HPOP is in place and working, you’ll want to maintain the whole oil system to avoid future problems. Here are a few tips:

- Regular Oil Changes: The HEUI system shears and stresses the engine oil, and dirty oil can clog the IPR or score the HPOP. Stick to a strict oil change schedule and use a good quality diesel-rated oil. Many 6.0 owners swear by synthetic oil for smoother injector operation.

- Use Oil Additives if Needed: Some choose to use additives like Rev-X or Archoil to reduce stiction in injectors; while this is more for injector spool valve issues, any improvement in oil performance can indirectly help the HPOP by keeping injectors flowing freely, reducing the strain on the pump.

- Fuel Filters and EGR Maintenance: Keep your fuel filters changed and address any EGR cooler issues promptly. A failing EGR cooler can lead to coolant in the oil, which is very bad for the HPOP and injectors. Bostech’s EGR cooler is a solid upgrade. Essentially, a healthy overall engine will create a better environment for the HPOP to last.

- Monitor ICP and IPR: It’s not a bad idea to occasionally monitor your ICP pressure and IPR duty cycle with a scanner during normal operation. This can give you early insight if things start to go out of range. For instance, if over time you see your IPR at idle creeping higher than normal, it might indicate some leakage beginning. Catching it early, maybe replacing an O-ring or seal, can prevent a breakdown.

- Keep Up with Bulletproofing Mods: The 6.0 has a list of known weaknesses: head studs, oil cooler, EGR, FICM, etc. Addressing those methodically will result in a much more reliable truck overall. The HPOP was one item on that list; so if you’ve just tackled it, give yourself a pat on the back and then continue with any other upgrades/updates the truck might need.

By following this guide, you should have a comprehensive understanding of the 6.0 Powerstroke HPOP and be well-prepared to deal with any HPOP issues. From how it works, to diagnosing a failure, deciding on repair vs replace, performing the replacement, and taking care of the system afterward, we’ve covered all the critical points.

Owning a 6.0 Powerstroke can be a love-hate relationship at times, but with the right knowledge and a bit of elbow grease, you can turn it into a love-love relationship. Address that HPOP, update those weak links with Bostech’s HPOPs and kits, and your 6.0 can be as reliable as ever. Happy wrenching!