What Is Diesel Engine Blow-By? Why It Happens and How to Avoid It

Sep 1st 2021

Blow-by is a common condition that affects most engines, whether they run on gas or diesel. When gas in the cylinder bore is under too much pressure, it leaks past the piston rings and into the crankcase, causing blow-by.

Ever experienced clouds of exhaust fumes, sputtering noises and rough idling sounds while driving? Your car may be suffering from a bad case of engine blow-by. While it’s inconvenient in the short-term, this condition can lead to more serious damage down the road, like sapped fuel efficiency or worse. The problem is, you probably won’t notice it for a while unless you know what to look for. In this guide, we’ll help you learn how to spot the problem and prevent it before it’s too late with the right diesel parts.

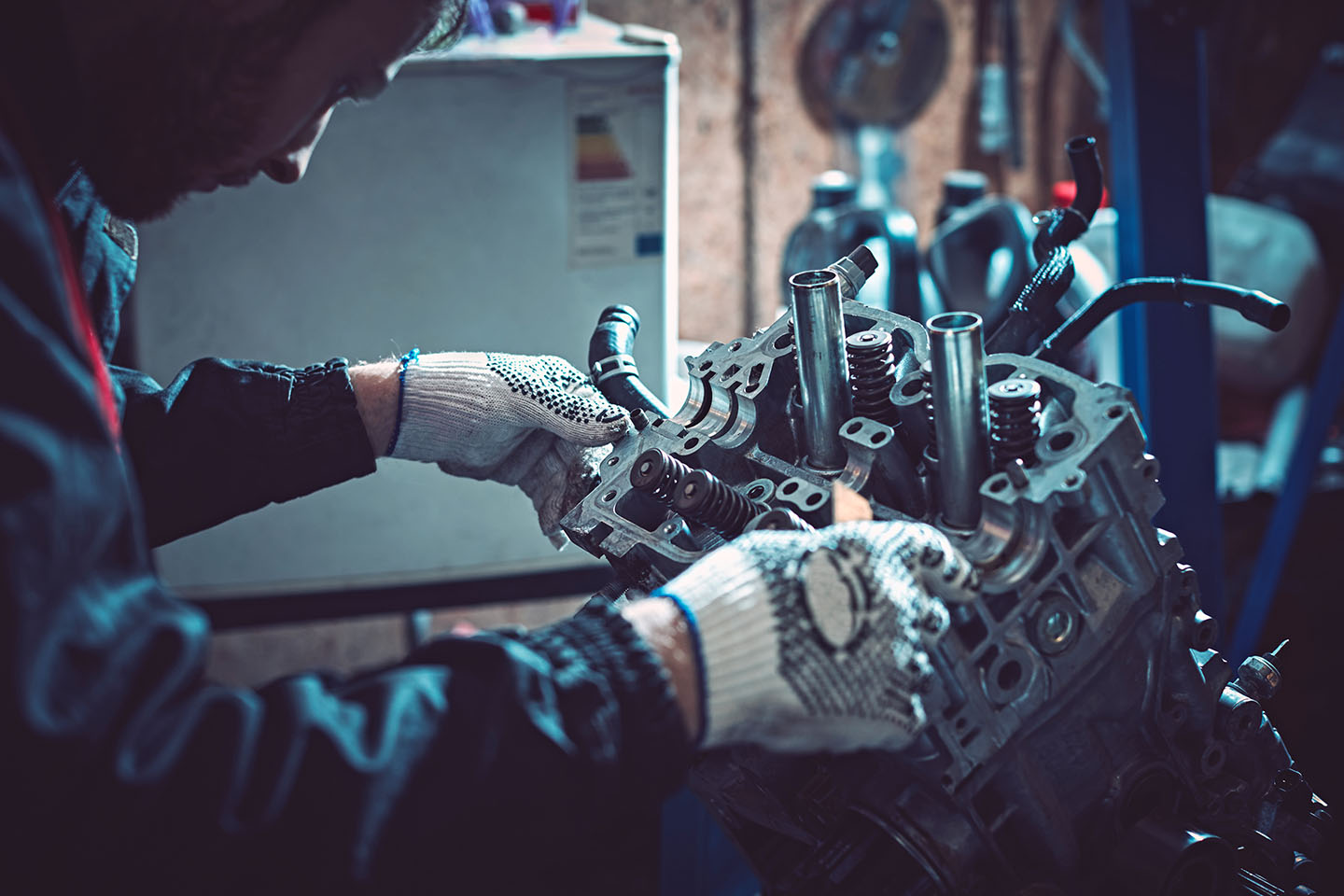

Source: Maren Winter/Shutterstock.com

What Causes Diesel Engine Blow-By?

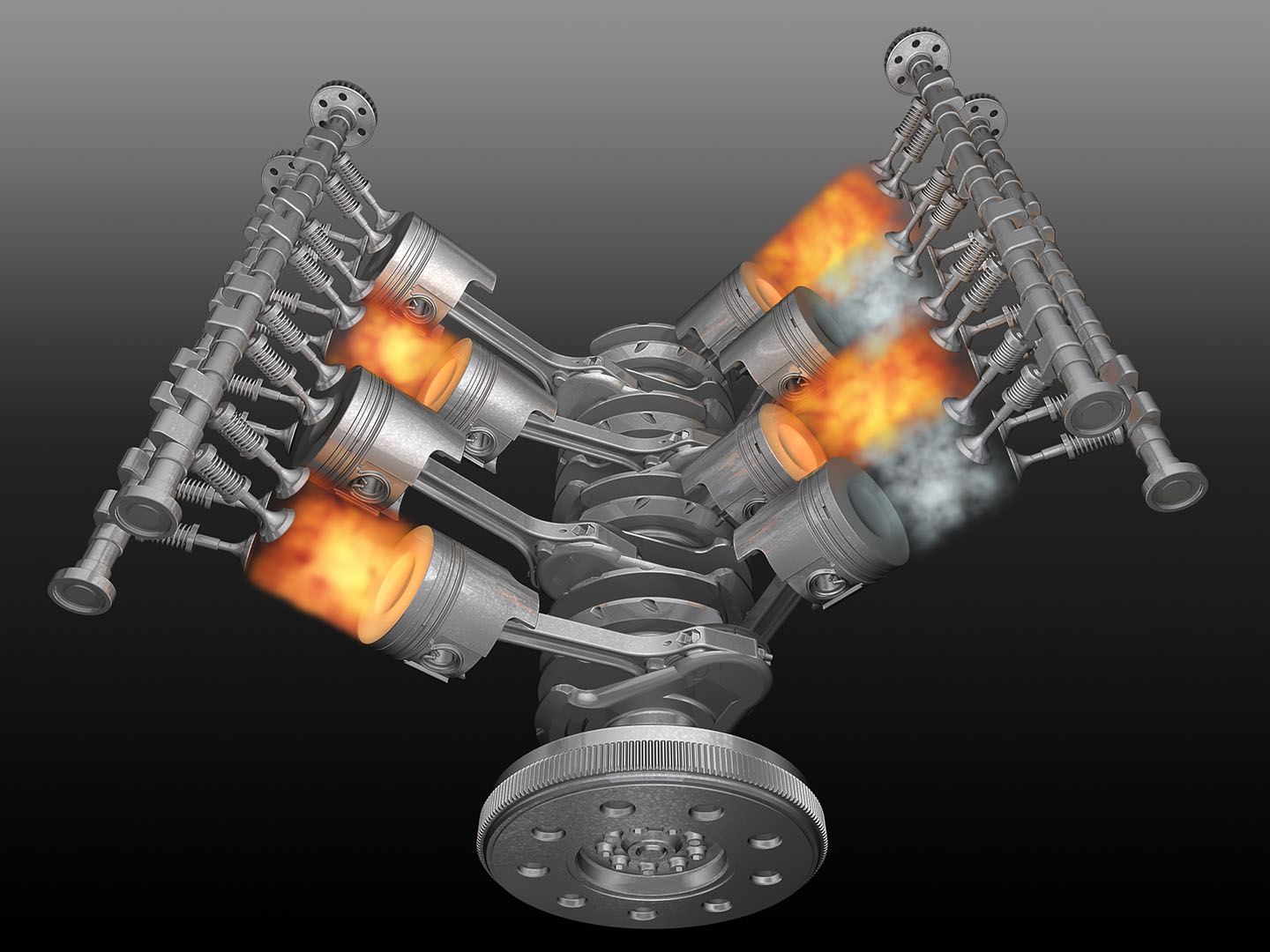

Diesel blow-by happens when there is too much pressure in the combustion cylinder, typically greater than that of the oil pan. As pressure builds, the air and gas eventually need to escape, breaking through the piston rings and into the crankcase.

Cylinder pressure will vary from time to time. The piston rings should seal to prevent leakage into the crankcase, but the chance of blow-by increases with mileage and vehicle age. If the cylinder or piston rings are damaged, they will lose their seal, which leaves you more vulnerable to blow-by. It’s also possible the rings are sticking to the walls of the cylinder, which is why regular maintenance is so important.

Even the best diesel engines suffer from blow-by from time to time. However, some variable-valve diesel engines come with sensors to reduce excess pressure. The sensors send data to the engine control module (ECM) to account for irregular gas pressure. There could also be a problem with the engine brakes, which regulate the combustion cylinder.

Compound, turbo-charged or performance-based diesel engines can be more vulnerable to the condition as the cylinder and piston rings experience additional wear and tear.

Source: SergeyKlopotov/Shutterstock.com

Testing for Diesel Engine Blow-By

It usually takes several weeks or days, depending on mileage, for drivers to notice something’s wrong. By that point, the blow-by will have already damaged the cylinder and crankcase. But there are some telltale signs of the condition that can help you spot it from a mile away.

- Listen for Noises That Sound Off — With blow-by, you’ll usually notice loud sputtering noises coming from the engine, which is always a bad sign. Listen for rough idling sounds and misfiring.

- Look for Clouds and Fumes — You might notice clouds or exhaust fumes coming from the engine. Watch out for white smoke coming off the oil-fill tube or valve covers. This means there’s too much pressure in the crankcase.

- Perform a Leakdown Test — For a more thorough breakdown of the engine, you’ll need to conduct what’s known as a leakdown test, which measures the percentage of blow-by. Use a dual-gauge testing tool to measure how much pressure is going into the combustion cylinder and how much pressure is escaping. The loss percentage shows the overall condition of the cylinder and engine. The test takes around two hours to complete. Have your local mechanic check the cylinder if you don’t have access to this equipment.

Source: Nikonaft/Shutterstock.com

How to Avoid Diesel Engine Blow-By

As we already mentioned, even the best engines will occasionally experience blow-by. With that said, there are a few key things you can do to prolong it or prevent it altogether.

- Maintain the Piston Rings — The best way to avoid blow-by is to make sure your combustion cylinder is working properly by maintaining the piston rings. They should seal properly to avoid leakage. Use Total Seal “gapless” high-performance pistons to close the second ring’s end gap.

- Use Oil Treatments — It’s also a good idea to use oil treatments like Stiction Eliminator or Diesel Extreme to keep your piston rings lubricated so they don’t stick to the walls of the chamber. There’s some debate as to whether they actually work. They’re not a cure-all, but they will reduce blow-by if you use them on a regular basis.

- Install an Oil Separator — Consider installing an oil separator, which removes oil from combustion gases to reduce pressure in the crankcase. If you have an older engine, you can also use a vent tube to reduce pressure in the combustion chamber.

- Replace the ICP Sensor— If you notice a rough idle, there may be a problem with your injection control pressure (ICP) sensor or the injection pressure regulator (IPR) valve, which regulates oil pressure in the injectors coming from the high-pressure oil pump. You’ll need to use diagnostic equipment to test the IPR valve, during which the duty cycle of the IPR valve is set to minimum and maximum values. If the oil pressure doesn’t change, the valve is broken. You can also try unplugging the ICP to see if that solves the problem, in which case, the sensor would be the culprit. Drivers can shop for new IPR valves online if they need a replacement.

It’s always best to maintain and replace your diesel parts as needed, especially if you like to put your engine through the wringer. Keep this information in mind to keep blow-by at bay.