What is an EGR Cooler? A Complete Guide for Diesel Owners

Jun 2nd 2025

Table of Contents

2. What Exactly Is an EGR Cooler (and What Does It Do)?

3. How EGR Coolers Work in the Diesel EGR System

4. EGR Coolers in Different Diesel Engines

4.2 International (Navistar) Engines

4.3 Ford Power Stroke 6.0L Example

5. Common Symptoms of a Failing or Clogged EGR Cooler

6. Common Causes of EGR Cooler Failure

7. Diagnosing a Bad EGR Cooler: How to Confirm the Issue

8. Tips for Choosing a Quality EGR Cooler Replacement

9. Keeping Your EGR System Healthy

1. Introduction

If you own a diesel truck, you’ve likely heard about the EGR cooler but might not know exactly what it does or why it’s important. An EGR cooler, or Exhaust Gas Recirculation cooler, is a vital component in modern diesel engines, helping control emissions and protect engine health. In this guide, we’ll explain in simple terms what an EGR cooler does, how it works with your EGR valve, and why it’s critical for your truck’s performance. We’ll also cover signs of a failing cooler, like white exhaust smoke or coolant loss, common causes of failure, how to diagnose issues, and tips for choosing a high-quality replacement, such as those available from Bostech Auto. By the end, you’ll be equipped to maintain your EGR cooler and keep your diesel running strong.

2. What Exactly Is an EGR Cooler (and What Does It Do)?

An EGR cooler is like a mini radiator for your exhaust gases. It’s a key part of the exhaust gas recirculation system, which reduces harmful emissions in diesel engines. The cooler’s job is to lower the temperature of hot exhaust gas before it’s sent back into the engine’s intake. It does this by passing the exhaust through a heat exchanger where engine coolant absorbs the heat, cooling the gas. This cooled, inert exhaust is then mixed with intake air without spiking combustion temperatures.

Why does this matter? It’s all about cutting nitrogen oxide emissions, or NOx. High combustion temperatures cause nitrogen and oxygen in the air to form NOx, which contributes to smog and acid rain. The EGR system lowers peak combustion temps by diluting the air-fuel mix with inert exhaust gas. Cooling the exhaust first makes this process more effective at reducing NOx. In short, the EGR cooler keeps your truck cleaner by controlling combustion heat.

Using cooled exhaust has little impact on engine performance during normal driving, yet it significantly reduces NOx pollution. Without a cooler, hot exhaust could raise engine temps or cause knocking. That’s why automakers began including EGR coolers in diesels around the early 2000s, when emissions regulations tightened. It’s a clever way to balance clean operation and engine safety.

Cummins 5.9L ISB Reman EGR Cooler with Bracket and Gasket Kit 2002-2006

3. How EGR Coolers Work in the Diesel EGR System

To get how an EGR cooler functions, let’s look at its place in the engine. It’s typically positioned between the turbocharger and the EGR valve. After exhaust gas exits the engine and passes through the turbo, a portion is routed through the cooler before reaching the EGR valve. The valve, controlled by the engine computer, meters how much cooled exhaust flows into the intake manifold, opening only under specific conditions, like cruising or moderate loads.

Inside the cooler, it’s built like a radiator or oil cooler. Hot exhaust gases flow through tubes or passages, while engine coolant circulates around them, absorbing heat through the walls. By the time the exhaust exits, it’s transferred much of its heat to the coolant, which is then carried to the main radiator for dissipation. The result is exhaust gas that’s much cooler when it hits the EGR valve.

In summary, the EGR cooler takes hot exhaust, cools it with engine coolant, and helps reduce NOx emissions. The cooled, low-oxygen exhaust mixes into the intake air via the EGR valve, keeping cylinder temperatures down. The cooler and valve work together; the valve manages flow, the cooler handles temperature. A Detroit Diesel engineer noted in 2002 that EGR coolers were “the simplest way to reduce NOx,” using existing coolant without extra fluids.

One key point: the heat from the exhaust ends up in your cooling system. This means your radiator and coolant work harder when EGR is active. Engineers design for this, but a failing cooler, like one with an internal leak, can cause issues such as coolant loss or overheating, which we’ll explore later.

4. EGR Coolers in Different Diesel Engines

EGR coolers vary in design across engines, but their purpose remains the same. Whether you’re running a Cummins, a Ford PowerStroke by International Navistar, or another diesel, the cooler chills exhaust gas. Let’s look at some examples, with links to relevant products from Bostech Auto.

4.1 Cummins Engines

Cummins adopted cooled EGR in the mid-2000s, notably with the 6.7L in Ram trucks from 2007 onward. These coolers are built for durability in continuous duty. Post-2010, Cummins paired EGR with SCR (Selective Catalytic Reduction using DEF), easing the EGR system’s load. By 2014, this combo improved reliability. Still, the cooler is crucial. A failure, like a cracked core, brings white smoke or coolant loss. For 2010–2022 6.7L Cummins engines, Bostech offers a remanufactured EGR cooler with upgraded stainless steel tubing, designed to eliminate common failure points.

4.2 International (Navistar) Engines

From 2008 to 2012, International’s MaxxForce diesels relied heavily on EGR without SCR, requiring massive coolers, some weighing 50 pounds, to handle high exhaust volumes. These were central to emissions control but prone to leaks, often pressurizing the cooling system and expelling coolant. Navistar later adopted SCR, but the lesson stuck: heavy EGR stresses coolers. For 2008–2012 MaxxForce DT engines, Bostech provides a remanufactured EGR cooler with stainless steel upgrades, built for durability.

4.3 Ford Power Stroke 6.0L Example

The 6.0L Power Stroke in 2003–2007 Ford trucks, made by Navistar, is infamous for EGR cooler failures. Its factory cooler used thin, oval coolant tubes that cracked under thermal and pressure stress, especially with coolant clogs. A failure sent coolant into the intake, causing white steam and potential engine damage. Upgraded replacements are now standard. Bostech offers EGR coolers for 6.0L PowerStroke engines, featuring robust stainless steel to prevent repeat issues.

Every diesel, from light-duty pickups to Class 8 semis, uses cooled EGR. Some, like the Ford 6.4L Power Stroke, use dual coolers for extra capacity. Regardless of design, your diesel has an EGR cooler keeping NOx down and the engine safe. When it fails, you’ll face similar symptoms across brands, as we’ll see next.

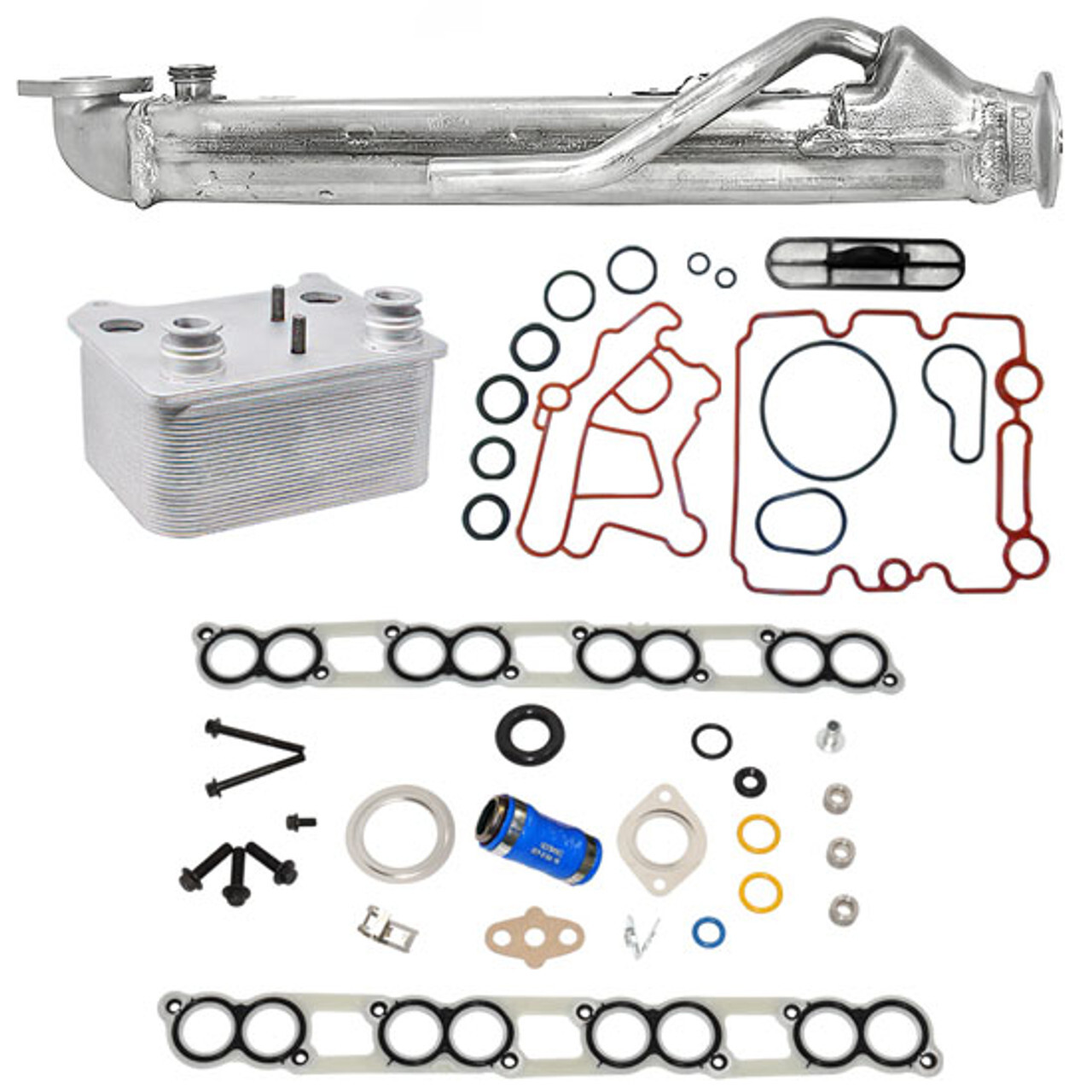

Ford 6.0L / International VT365 Reman EGR Cooler Kit with Oil Cooler 2004-2010

5. Common Symptoms of a Failing or Clogged EGR Cooler

How do you spot a failing EGR cooler? Several telltale signs stand out, but they can mimic other issues, like head gasket problems. Catching them early is key. Here are the main symptoms.

- White smoke or steam from the exhaust: Persistent white “smoke” after warmup is often steam, caused by coolant leaking into the exhaust and vaporizing. A cracked cooler or failed gasket can let coolant enter, turning to steam at the tailpipe. If it’s not just cold-weather condensation, it’s a red flag. Note: head gaskets can also cause this, so further checks are needed.

- Unexplained coolant loss: Need to top off coolant often with no visible leaks? The EGR cooler’s a likely culprit. Internal ruptures can send coolant into the exhaust or intake, not onto the ground. You might notice the overflow tank dropping without explanation. No external leaks plus low coolant often points to the cooler.

- Engine overheating or running hot: A failing cooler can trigger overheating. Leaking coolant lowers levels, raising temps. Exhaust gas entering the cooling system through a crack can add air pockets or pressure, pushing coolant out the overflow. If your diesel runs hotter than usual or spills coolant, suspect the cooler. Overheating demands quick action to avoid engine damage.

- Visible coolant around the EGR cooler or exhaust manifold: While most failures are internal, you might spot external leaks from the cooler or its seals. Look for coolant residue or wet spots with a sweet smell near the cooler. Any leakage there signals a problem, whether it’s the cooler, hoses, or gaskets.

- Check Engine Light (CEL) comes on: A bad cooler can trigger the CEL. Clogged with soot, it may reduce EGR flow, setting off codes like P0401 for “EGR insufficient flow.” High exhaust temps from a faulty EGR system can trip temp sensors. If the light’s on, scan for codes; they might point to the EGR system. Newer diesels may enter limp mode to protect against damage.

- Poor performance or turbo issues: A failing cooler can hurt performance. Carbon clogs can restrict exhaust flow, impacting turbo function or increasing backpressure, leading to sluggishness, slow acceleration, or black smoke from unburned fuel. Coolant in the intake from a leak can disrupt the air-fuel mix, causing rough running or misfires. In rare cases, a major leak might hydro-lock the engine, stopping it abruptly.

- Odd findings upon inspection: Checking the EGR valve can reveal clues. Normally sooty, it might be wet or unusually clean if coolant’s passed through. Sticky goo from coolant and carbon mixing is another sign. If the valve looks off, the cooler’s likely leaking.

If you see these symptoms, act quickly. A failing EGR cooler can lead to severe issues, like engine hydro-lock. Next, we’ll cover what causes these failures.

6. Common Causes of EGR Cooler Failure

EGR coolers operate in brutal conditions, handling hot, sooty exhaust and warm coolant. Over time, this takes a toll. Knowing the causes helps you prevent issues and choose better replacements. Here’s what typically goes wrong.

- Soot Buildup and Clogging: Diesel exhaust carries carbon particles, which can coat or clog the cooler’s passages. Excessive idling or poor combustion increases soot, insulating the cooler and causing hotspots. Severe clogs block EGR flow, raising emissions and backpressure, which can overheat the cooler. Regular highway driving and periodic cleaning help.

- Thermal Stress and Metal Fatigue: Coolers face extreme temperature swings, from hundreds of degrees down to cooler levels, cycling thousands of times. This expansion and contraction fatigues the metal, cracking tubes or warping joints. Thin-walled or soldered designs are especially vulnerable. Heavy towing or hard driving accelerates this.

- Coolant Side Restrictions or Corrosion: Poor coolant maintenance, using old or incorrect coolant, can corrode the cooler’s passages. Aluminum or soldered coolers are prone to damage if additives deplete. In engines like the 6.0L Power Stroke, a clogged oil cooler can restrict coolant flow to the EGR cooler, causing local overheating or boiling. Proper coolant is critical.

- Pressure and Vibration Stress: Turbocharged exhaust pulses hammer the cooler, especially with variable geometry turbos. These pressure changes, plus engine vibrations, can crack welds or loosen joints. Larger coolers feel this more. Manufacturers use brackets to minimize damage, but wear persists, particularly in heavy-duty use.

- Poor Original Design or Materials: Some factory coolers prioritize size and efficiency over durability. The 6.0L Power Stroke’s thin tubes are a classic example, prone to rupture. Weak materials or seams may pass lab tests but fail in real-world conditions. Aftermarket upgrades, like those from Bostech, often address these flaws.

- External Factors (Engine Issues): Other problems can stress the cooler. A clogged DPF raises exhaust temps, cooking the cooler. A blown head gasket overpressurizes the cooling system. Even a blocked radiator increases heat. Maintaining the entire engine, cooling, fuel, and aftertreatment systems, is essential.

Failures often stem from multiple factors, like a weak cooler clogged with soot under heavy load. Proactive maintenance, like proper coolant and timely fixes, can prevent trouble.

7. Diagnosing a Bad EGR Cooler: How to Confirm the Issue

Symptoms alone don’t confirm a bad cooler; they overlap with issues like head gaskets. Proper diagnosis avoids wasted repairs. Here’s how to verify.

- Check for coolant in the exhaust: See steam? Have someone safely sniff the exhaust; coolant has a sweet smell. Remove the downpipe or EGR valve to check for residue. Listen near the cooler after shutdown; hissing or gurgling suggests coolant boiling in hot passages.

- Monitor coolant level and pressure: With the engine cold, use a pressure tester on the radiator or degas bottle. If pressure drops without external leaks, coolant may be escaping internally, possibly via the cooler. During a cold start, rapid pressure rises or vapor in the overflow can indicate exhaust gas in the coolant. A block tester can detect combustion gases in the coolant, pointing to the cooler or a head gasket.

- Inspect the EGR valve and intake: Remove the EGR valve if accessible. A wet or clean valve suggests coolant ingress. Look for coolant in the intake manifold or EGR passages. If the valve’s just sooty, leaks are unlikely, but clogs remain possible.

- Scan for diagnostic trouble codes (DTCs): Use an OBD-II scanner. EGR codes, like P040x, or temp-related codes can signal cooler issues. Low flow might indicate clogs; temp codes suggest poor cooling. Even without a CEL, check for pending codes.

- Rule out other causes: White smoke might be a head gasket; a compression test can confirm. Overheating could stem from a thermostat or fan clutch. Temporarily bypassing the cooler’s coolant lines (off-road only) can test symptoms, but consult a mechanic to avoid damage.

- Compression and fluid tests: Coolant in the engine might contaminate oil; a lab test can confirm. If hydro-lock’s suspected, a compression test checks for damage like bent rods from coolant ingestion.

Diagnosis takes patience. If signs like sweet steam, low coolant, and a clean valve align, the cooler’s likely the issue. Don’t drive long with a suspected failure; coolant in the engine can cause catastrophic damage.

8. Tips for Choosing a Quality EGR Cooler Replacement

If your cooler’s bad or you’re upgrading proactively, picking the right replacement is crucial. Here’s how to choose a durable EGR cooler, with options from Bostech Auto.

- Consider Upgraded Aftermarket Coolers: If the OEM cooler failed due to design flaws, opt for an aftermarket upgrade. Bostech’s coolers, like the Cummins 6.7L ISB EGR Cooler, use 304 stainless steel tubing for better heat transfer and durability, addressing factory weak points. Stainless steel resists corrosion and handles thermal stress better than stock materials.

- OEM vs. Aftermarket: If your original cooler lasted well and isn’t known for issues, an OEM replacement ensures fit and emissions compliance. But for engines prone to cooler failures, like the 6.0L Power Stroke, aftermarket options like Bostech’s Ford PowerStroke EGR coolers offer superior longevity. Check forums and reviews for owner experiences, and stick to reputable brands.

- Match the Cooler to Your Engine: Coolers are engine-specific. Match the part to your engine’s make, model, year, and displacement. For example, use a 6.7L Cummins EGR cooler for a 6.7L engine, or a 6.0L PowerStroke cooler for a 6.0L. Bostech’s site lets you filter by engine or OEM part number. Compare the new cooler to your old one for confirmation.

- Quality Assurance and Testing: Choose coolers with rigorous testing. Bostech’s remanufactured EGR coolers undergo multi-point pressure and fitment tests to ensure leak-free performance []. A 24-month unlimited mileage warranty, like Bostech’s, signals confidence in durability. Some, like the Mercedes-Benz MBE906 EGR Cooler, even offer a lifetime warranty.

- Avoid Cheap Knockoffs: Bargain coolers often use subpar materials or welds, failing quickly and risking engine damage. Stick to trusted suppliers like Bostech, whose International Navistar EGR coolers are built for reliability. Quality matters in the harsh conditions coolers face.

- Upgraded Design Features: Look for design improvements. Bostech’s coolers, such as the MaxxForce DT EGR Cooler, use stainless steel tube designs instead of fragile OEM cores, reducing failure points []. Features like thicker end plates or flexible joints enhance longevity. While BulletProof Diesel is popular for 6.0L upgrades, Bostech’s coolers offer comparable durability at competitive prices [].

- Compliance (Street Legal vs. “Delete”): Replacing the cooler is the only road-legal option. EGR deletes are for off-road use only, violating emissions laws and risking CELs. Bostech’s coolers, like the Ford 6.7L EGR Cooler, are direct-fit and compliant, though some can’t ship to California or Colorado due to strict regulations []. Check local emissions rules, especially for CARB certification in California.

Research is key. Bostech offers EGR coolers for Ford PowerStroke, Cummins, GM Duramax, and International Navistar, with robust construction and warranties []. Installation can be complex, so use a repair manual for DIY or hire a mechanic. After install, bleed the coolant system to avoid air pockets, which can cause hot spots.

9. Keeping Your EGR System Healthy

Maintaining your EGR cooler is about keeping your engine in top shape. Here are some tips.

- Drive your truck! Short trips and idling build soot. Regular highway runs at full temp help burn off deposits.

- Quality fuel and tuning: Poor combustion or rich running increases soot, clogging the cooler. Maintain injectors and use clean fuel.

- Cooling system maintenance: Flush coolant on schedule, use the correct type, and ensure the water pump, thermostat, and radiator are solid. The cooler depends on healthy coolant.

- Regular inspections: If accessible, check the EGR valve and cooler for leaks or heavy soot. Some owners clean the cooler every 50,000 miles with specialized cleaners, but be gentle to avoid damaging delicate internals.

10. Conclusion

The EGR cooler isn’t glamorous, but it’s essential for your diesel’s longevity and emissions control. By cooling exhaust gases, it keeps combustion temps in check and cuts NOx pollution. Understanding it helps you spot issues early and make informed maintenance choices.

If you notice white smoke, vanishing coolant, or a check-engine light, don’t wait. These signal potential EGR cooler problems, and quick action prevents worse damage. Diagnose carefully, then replace a faulty cooler with a quality unit, like those from Bostech Auto. Their upgraded stainless steel coolers offer longer life and peace of mind.

Stick to regular maintenance and invest in reliable parts. A trusted supplier like Bostech provides EGR coolers and gasket kits for a proper install. A healthy EGR cooler supports a healthy engine. Keep it cool, keep it clean, and your diesel will deliver miles of reliable service.

For replacements, explore Bostech’s range of durable EGR coolers for Ford, Cummins, GM, and more. With direct-fit designs and strong warranties, you can tackle EGR cooler issues confidently. Safe driving and happy wrenching!