What Does a High Pressure Oil Pump Do?

Oct 5th 2021

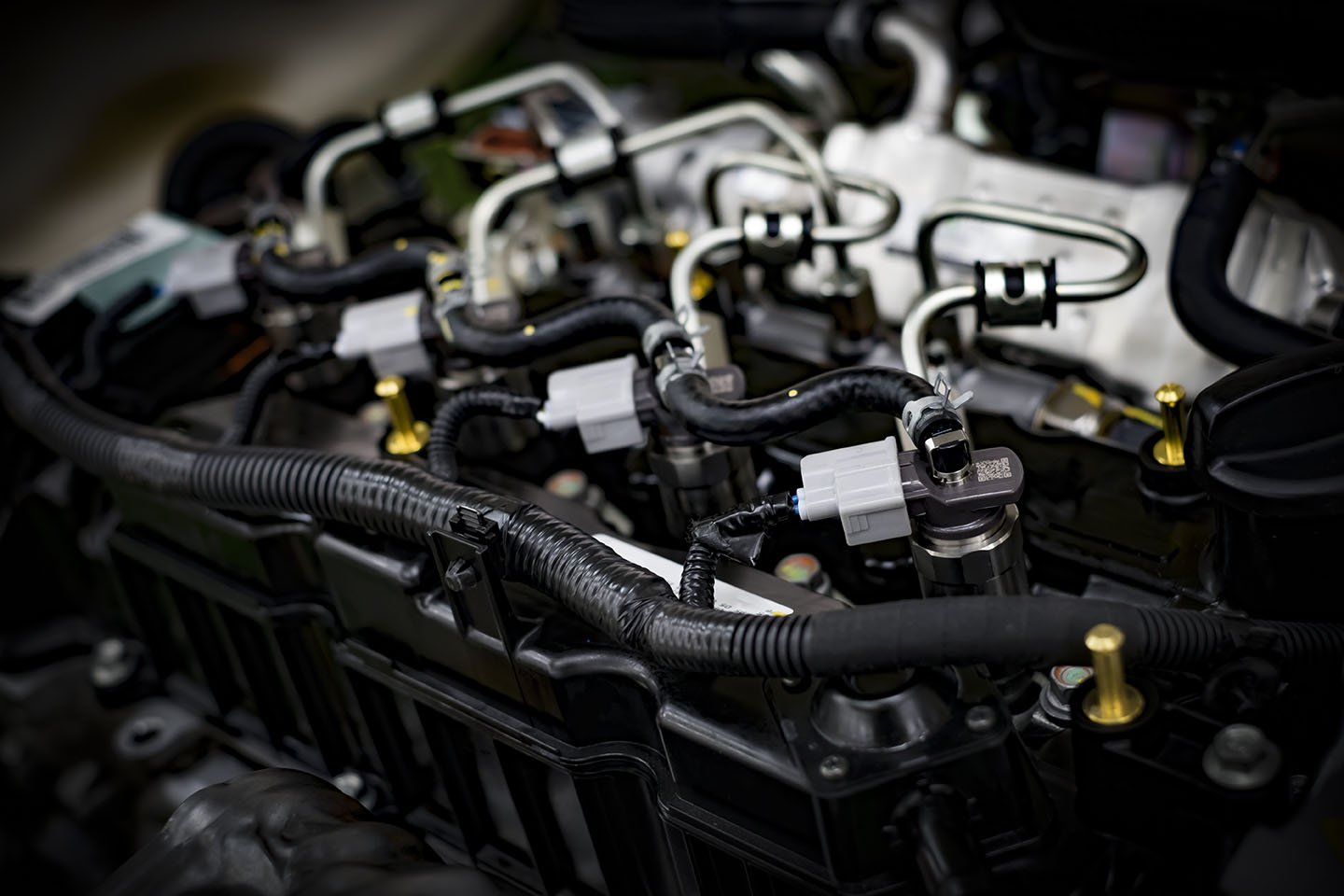

A high pressure oil pump (HPOP) is a crucial part of any Ford Powerstroke engine. Just like the name implies, it is a high pressure pump that sends oil to other parts of the engine, which provides lubrication. The flow of oil is the river that keeps the engine moving. Without it, the entire engine would screech to a halt. Engine oil needs excess pressure to push through all the nooks and crannies of the engine. That’s why the HPOP is so important.

The HPOP is a relatively new invention. Older versions of the Powerstroke engine utilized what’s known as a HEUI system, which stands for a hydraulically activated, electronically controlled, unit injectorfuel system. This technology is considered outdated by today’s standards, but many vehicles on the road still use this process.

The HPOP helps the HEUI system do its job in more ways than one. Learn more about high pressure oil pumps and how they keep your engine running.

Using a High Pressure Oil Pump

Unlike conventional pump systems, the HPOP doesn’t create pressure through traditional means. Oil pressure is based on how much oil the pump is sending through the pistons. Many HPOPs have seven pistons as part of a swashplate-style pump. The location and functionality of the pump depend on the manufacturer.

For example, the Boschhigh-pressure oil pump is gear driven and works with a 7.3L Powerstroke engine. It is externally mounted to the front cover at the front of the lifter valley. The drive gear isn’t timed to the cam or the pump.

However, a Siemens high-pressure oil pump sits in the crankcase at the rear of the 6.0L Powerstroke engine. It’s timed to the engine itself.

Locate the specific OEM for your HPOP to learn more about how it works.

Shop Diesel Parts Based on the Make and Model

The HPOP works in tandem with other components, including the fuel injection system and the turbocharger. It’s a part of a closed-loop injection control system that involves the Powertrain control module, injection pressure regulator, and the injection control pressure sensor.

The PCM is calibrated based on programmable inputs. It controls the injection pressure regulator, which regulates the amount of oil coming through the high pressure oil pump, usually with a range of 500 to 4,000 PSI. As the HPOP releases oil into the pistons, the injection control pressure sensor monitors the flow. It will then signal back to the PCM to make sure everything is working correctly.

The Injector Firing Process

When the injectors are getting ready to fire, the electronic solenoid gets energized by the injector drive module (IDM). This pulls the poppet valve off its seat, which closes the oil drain pathway, making way for high-pressure oil.

The oil will then transfer its pressure through the poppet valve, located on top of the intensifier piston. The intensifier piston has seven times more surface area than the plunger, which means high-pressure oil with 3,000 PSI injection control pressure will convert to 21,000 PSI of fuel injection pressure as it enters the combustion chamber. Aftermarket injectors with large plungers can help reduce the multiplying force of the intensifier piston.

Find 6.0 IPR Valves for a Better Firing Process

The high-pressure oil on the intensifier piston will then force the plunger down, which raises the nozzle needle. The fuel is then pressurized in the plunger cavity. The nozzle is then opened, sending fuel into the combustion chamber. The nozzle is similar to other nozzles except that it uses a check ball to seal the plunger during the downstroke, which prevents fuel from leaking out.

As the intensifier piston and plunger stroke downward, the void at the top of the injector is filled with high-pressure oil that’s been waiting in the oil rails. The injection pressure regulator valve and HPOP move the oil once the pistons have fired.

Shop for New IPR Valves to Maintain Your HPOP

Problems with the HPOP

The HPOP is designed to last forever but it will lose its power over time. While it’s rare for the pump to stop working entirely, you may notice a burning smell under the hood if the pump has an oil leak. Oil may also be leaking out of your exhaust, creating what looks like blue smoke. A lack of oil or oil pressure is bad news for the entire engine. If the oil can’t get where it needs to go, metal parts will start to grind against each other. This can lead to a blown gasket or leaks in the many hoses that transport fluids in the engine.

Lots of things can go wrong with the oil system, not just the HPOP.

If you notice some of these problems or the engine is starting, there may be a problem with the IPR valve, which controls the pressure of the oil flowing through the engine, or the injection control pressure (ICP) sensor, which informs the IPR valve how much pressure is needed to distribute the oil. There could be a faulty connection between the valve and sensor. Excess carbon and debris can also clog the IPR valve, slowing the flow of oil.

You may need to replace your ICP sensor or IPR valve as these issues arise. Buy a replacement from a quality aftermarket part manufacturer, such as DieselSite, to keep your engine going strong. No diesel engine should go without quality oil.

Poor oil circulation also puts extra pressure on the gaskets and seals that keep these fluids in place. A broken O-ring or gasket can cause a leak in the crankcase, which will result in smoke coming out of the hood. Keep an eye on these parts and replace them as they age to avoid damaging the other components of the engine.

The pump is also only as good as the oil that goes into it. You’ll need to change your oil often and clean the oil filter as needed to remove excess dirt and soot. The oil cooler may also be acting up. If the oil is too hot, it can’t lubricate the many parts and components of the engine.

Most of these issues should activate the check engine light, but the problem may start long before these symptoms appear. Check under the hood regularly to avoid driving with a fault or damaged part.

Keep these tips in mind as you get more comfortable working on or with your high-pressure oil pump. Every driver should be familiar with this crucial component and how it feeds high pressure oil to other parts of the engine.

If you need a new high-pressure oil pump or IPR valve, replace them before the problem gets any worse.

Image Credits:

MR.TEERASAK KHEMNGERN/Shutterstock.com