How to Clean Diesel Fuel Injectors: Tools, Techniques, and Tester Insights

Aug 1st 2025

Table of Contents

- Understanding Diesel Fuel Injectors and Why They Get Dirty

- Recognizing the Signs of Clogged Diesel Fuel Injectors

- Manual Cleaning Methods for Diesel Fuel Injectors

- Chemical Cleaning Methods: In-Tank and Direct Injection

- Using a Diesel Fuel Injector Tester: The Key to Verification

- Best Practices for Maintaining Clean Diesel Fuel Injectors

- Professional vs. DIY Cleaning: Making the Right Choice

- Advanced Injector Cleaning Techniques and Considerations

- Common Mistakes to Avoid When Cleaning Diesel Fuel Injectors

- Frequently Asked Questions (FAQ)

Your diesel engine relies on precise fuel delivery to run efficiently, and the fuel injectors are the critical components that make this happen. When these injectors become clogged or dirty, you'll notice decreased performance, rough idling, increased fuel consumption, and potentially expensive repairs down the road. Understanding how to properly clean diesel fuel injectors can save you thousands of dollars and keep your engine running smoothly for years to come.

Think of your diesel fuel injectors as precision instruments, similar to the nozzle on a high-end paint sprayer. Just as a partially clogged paint nozzle creates uneven spray patterns and poor coverage, a dirty fuel injector disrupts the precise fuel atomization your engine needs for optimal combustion. This guide will walk you through everything you need to know about cleaning diesel fuel injectors, from recognizing the signs of clogged injectors to choosing between manual and chemical cleaning methods, and even how to use a diesel fuel injector tester to verify your results.

Whether you're a seasoned diesel mechanic or a dedicated DIY enthusiast looking to maintain your truck, understanding the intricacies of fuel injector maintenance is essential. We'll explore both professional-grade techniques and accessible methods you can perform in your garage, ensuring you have the knowledge to make informed decisions about your diesel's fuel system maintenance.

Understanding Diesel Fuel Injectors and Why They Get Dirty

Before diving into cleaning techniques, it's crucial to understand what diesel fuel injectors do and why they're prone to contamination. Modern diesel fuel injectors operate under extreme conditions, with common rail systems pushing fuel at pressures exceeding 30,000 PSI through openings smaller than a human hair. This incredible precision makes them both remarkably efficient and unfortunately susceptible to contamination.

The primary culprits behind dirty diesel fuel injectors include carbon deposits from incomplete combustion, microscopic debris in fuel, water contamination, and the natural degradation of diesel fuel over time. Carbon buildup occurs when fuel doesn't burn completely, leaving behind residue that gradually accumulates on the injector tips. This process accelerates when engines idle frequently, run with poor quality fuel, or operate with other mechanical issues affecting combustion efficiency.

Water contamination presents another significant challenge for diesel fuel systems. Unlike gasoline, diesel fuel has a natural affinity for water, absorbing moisture from the air through condensation in fuel tanks. This water can cause corrosion inside injectors, create bacterial growth (diesel bug), and lead to injector failure if not addressed promptly. Additionally, modern ultra-low sulfur diesel fuel, while better for emissions, lacks some of the natural lubricating properties of older diesel formulations, potentially accelerating wear and deposit formation in injectors.

The quality of diesel fuel varies significantly depending on your location and supplier. Fuel from high-volume stations typically stays fresher, while diesel that sits in tanks for extended periods can develop gums and varnishes that contribute to injector deposits. Understanding these contamination sources helps explain why regular injector maintenance is essential, even for well-maintained engines.

Recognizing the Signs of Clogged Diesel Fuel Injectors

Identifying clogged or dirty fuel injectors early can prevent more serious engine damage and costly repairs. The symptoms often develop gradually, making them easy to overlook until they become severe. Here's what to watch for in your diesel engine's behavior.

Performance-Related Symptoms

The most noticeable sign of dirty injectors is often a decrease in engine performance. You might experience hesitation during acceleration, especially when the engine is under load. This occurs because clogged injectors can't deliver the precise amount of fuel needed for optimal combustion. The engine may feel sluggish or unresponsive, particularly when climbing hills or towing heavy loads.

Rough idling represents another classic symptom of injector problems. When one or more injectors aren't spraying fuel properly, the affected cylinders won't contribute their full power, creating an uneven idle. You might notice the engine shaking or hear an irregular rhythm at idle. In severe cases, the engine may stall at traffic lights or struggle to maintain idle speed without constantly adjusting the throttle.

Hard starting, especially in cold weather, often indicates injector issues. Clean injectors create a fine fuel mist that ignites easily, while dirty injectors may produce larger droplets or uneven spray patterns that resist ignition. You might find yourself cranking the engine longer than usual, or needing to use starting fluid more frequently.

Fuel Economy and Emissions Indicators

A sudden decrease in fuel economy often signals injector problems. When injectors can't atomize fuel properly, more fuel is needed to achieve the same power output. You might notice your fuel consumption increasing by 10% to 20% or more, even with no change in driving habits. This increased fuel consumption directly impacts your wallet and indicates inefficient combustion.

Black or white smoke from the exhaust provides visual evidence of injector issues. Black smoke indicates incomplete combustion due to excess fuel, often caused by injectors that are stuck partially open or creating poor spray patterns. White smoke, particularly on startup, can indicate unburned fuel passing through the engine, another sign of poor injector performance. Modern diesel engines with properly functioning injectors should produce minimal visible exhaust once warmed up.

Engine Knock and Unusual Noises

Diesel knock, while normal to some degree in diesel engines, becomes excessive when injectors malfunction. Properly functioning injectors create a controlled burn, while dirty injectors may cause fuel to ignite too early or too late in the combustion cycle. This mistiming creates a characteristic knocking or pinging sound that's louder than normal diesel clatter.

You might also hear a distinctive ticking or clicking sound from the engine, particularly at idle. This can indicate an injector that's sticking or not sealing properly. The sound often changes with engine speed and may be more pronounced when the engine is cold.

Check Engine Light and Diagnostic Codes

Modern diesel engines monitor injector performance through various sensors. When injectors begin to fail, the engine control module (ECM) often detects the issue and triggers the check engine light. Common diagnostic trouble codes (DTCs) related to injector problems include:

- P0201 through P0212: Injector circuit malfunctions for specific cylinders

- P1211 through P1222: Injector control pressure issues

- P2146 through P2149: Fuel injector group voltage problems

- Various misfire codes (P0300 series) indicating combustion issues

While these codes don't always mean the injectors need cleaning (electrical issues can trigger similar codes), they often point toward injector-related problems that cleaning might resolve.

Manual Cleaning Methods for Diesel Fuel Injectors

Manual cleaning represents the most thorough approach to restoring injector performance, though it requires removing the injectors from the engine. This method allows for complete disassembly, inspection, and cleaning of each injector component. While more labor-intensive than chemical cleaning, manual methods often produce superior results for severely contaminated injectors.

Tools and Equipment Needed

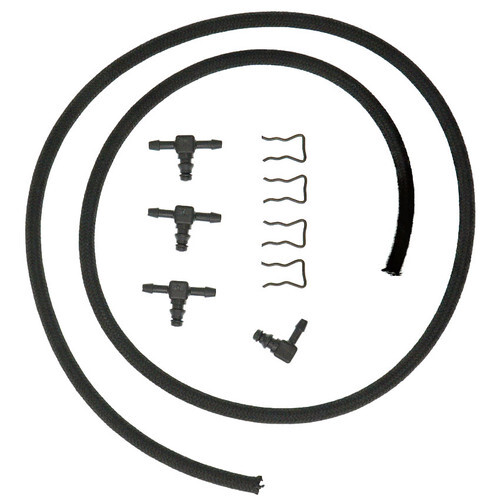

Successful manual injector cleaning requires specific tools and equipment. Essential items include:

- A quality injector puller tool designed for your specific engine

- Injector holding fixtures or a bench vise with soft jaws

- Ultrasonic cleaning tank (minimum 2-liter capacity)

- Brass wire brushes of various sizes

- Plastic picks and scrapers

- Compressed air source (filtered and dry)

- Clean diesel fuel or injector cleaning solution

- New injector sealing washers and O-rings

- Torque wrench for reinstallation

- Clean, lint-free cloths

- Safety equipment: gloves, safety glasses, and adequate ventilation

Professional shops often use specialized injector cleaning machines that combine ultrasonic cleaning with reverse-flushing capabilities. While these machines provide excellent results, they're expensive for occasional use. The methods described here achieve similar results using more accessible equipment.

Removing Diesel Fuel Injectors

Removing injectors requires patience and the right technique to avoid damage. Begin by thoroughly cleaning the area around each injector to prevent debris from falling into the open cylinder. Use compressed air and clean rags to remove all dirt and grime from the injector wells.

Disconnect the fuel lines carefully, using flare nut wrenches to avoid rounding the fittings. Cap or plug all open fuel lines immediately to prevent contamination. For common rail systems, the high-pressure lines must be handled with extra care, as they're precisely manufactured and easily damaged. Label each line and injector to ensure correct reassembly.

Remove the injector hold-down clamps or brackets, keeping track of their orientation. Some engines use individual clamps for each injector, while others employ a common rail that secures multiple injectors. Document the arrangement with photos before disassembly.

Extract the injectors using the appropriate puller tool. Never attempt to pry or hammer injectors out, as this can damage both the injector and the cylinder head. Apply penetrating oil around the injector base and allow it to soak if injectors are stuck. Work the puller gradually, alternating between injectors if multiple units are stuck. Some technicians prefer to run the engine briefly to warm and expand components before removal, but this requires extreme caution due to hot surfaces and fuel.

Disassembly and Cleaning Process

Once removed, carefully disassemble each injector according to manufacturer specifications. Not all injectors are designed for complete disassembly, so research your specific model before proceeding. For those that can be disassembled, work in a clean environment and organize components to prevent mixing parts between injectors.

Begin with external cleaning using soft brass brushes to remove carbon deposits from the injector body and nozzle area. Avoid using steel brushes or abrasive materials that could damage precision surfaces. Pay particular attention to the nozzle tip, where carbon buildup is typically heaviest.

Ultrasonic cleaning provides the most effective method for removing internal deposits. Use a commercial injector cleaning solution or a mixture of clean diesel fuel with a specialized additive. Set the ultrasonic cleaner to the manufacturer's recommended temperature (typically 140°F to 160°F) and run cycles of 10 to 15 minutes. Between cycles, use compressed air to blow out loosened debris.

For stubborn deposits, consider using a reverse-flushing technique. This involves forcing cleaning solution backwards through the injector using specialized adapters. While effective, this method requires careful pressure control to avoid damaging internal components.

After cleaning, rinse components thoroughly with clean diesel fuel or solvent. Use filtered compressed air to dry all passages completely. Inspect each component for wear, scoring, or damage that might require replacement rather than cleaning.

Reassembly and Testing

Reassemble injectors carefully, replacing all O-rings and copper sealing washers. These components should never be reused, as they compress during initial installation and won't seal properly if reinstalled. Use a light coating of clean engine oil on O-rings to ease assembly and prevent damage.

Before reinstalling cleaned injectors, they should be tested to verify proper operation. This is where a diesel fuel injector tester becomes invaluable. Testing confirms that cleaning was successful and identifies any injectors that may need replacement rather than cleaning.

Chemical Cleaning Methods: In-Tank and Direct Injection

Chemical cleaning offers a less invasive alternative to manual cleaning, allowing treatment of injectors without removal from the engine. While generally not as thorough as manual cleaning for severely clogged injectors, chemical methods work well for preventive maintenance and addressing mild to moderate contamination.

In-Tank Fuel Additives

The simplest chemical cleaning approach involves adding cleaning agents directly to the fuel tank. Quality diesel fuel injector cleaners contain detergents and solvents designed to dissolve deposits gradually as the treated fuel passes through the system. This method works best for:

- Preventive maintenance on regularly serviced engines

- Mild deposit buildup causing minor performance issues

- Supplementing other cleaning methods

- Ongoing maintenance between major services

When selecting in-tank cleaners, look for products containing polyetheramine (PEA) or polyisobutylene amine (PIBA), proven effective at removing carbon deposits. Avoid products making unrealistic claims or containing primarily petroleum distillates without active cleaning agents. Follow dosage instructions carefully, as over-concentration can damage fuel system components or cause excessive deposit removal that clogs filters.

For best results with in-tank cleaners, add the product to a nearly empty tank, then fill with fresh, high-quality diesel fuel. This ensures proper mixing and concentration. Run the engine under varying loads to circulate the treated fuel through the entire system. Some technicians recommend using a double dose for the first treatment on neglected engines, followed by regular maintenance doses.

Direct Injection Cleaning Systems

Professional direct injection cleaning provides more aggressive chemical treatment without injector removal. This method bypasses the fuel tank, delivering concentrated cleaning solution directly to the injectors through specialized equipment. The process typically involves:

Connecting a pressurized canister system to the fuel rail or supply line, temporarily bypassing the vehicle's fuel system. The cleaning solution, much more concentrated than in-tank additives, flows directly through the injectors while the engine runs. This allows for immediate, intensive cleaning action.

The engine runs on the cleaning solution for 15 to 30 minutes, during which time the powerful solvents dissolve deposits throughout the injector passages. Technicians vary engine speed during treatment to ensure thorough cleaning under different flow conditions. Some systems include special adapters allowing individual injector treatment for targeted cleaning.

Direct injection cleaning works particularly well for:

- Engines with moderate deposit buildup

- Addressing specific performance issues

- Situations where injector removal isn't practical

- As part of regular maintenance programs

Combination Approaches

Many technicians achieve optimal results by combining chemical cleaning methods. A typical approach might include:

Starting with a direct injection cleaning to address immediate performance issues, followed by running several tanks of fuel with quality additives to continue the cleaning process. This combination provides immediate improvement while ensuring ongoing deposit removal.

For severely neglected engines, technicians might perform direct injection cleaning, followed by an oil change (as some cleaning solution enters the crankcase), then maintain results with regular additive use. This comprehensive approach addresses both existing problems and prevents future buildup.

Using a Diesel Fuel Injector Tester: The Key to Verification

A diesel fuel injector tester serves as an essential diagnostic tool, allowing you to verify injector performance both before and after cleaning. Understanding how to properly use these testers helps determine whether cleaning will suffice or if replacement is necessary. Modern diesel fuel injector testers range from simple pop testers to sophisticated computerized systems that measure multiple parameters.

Types of Diesel Fuel Injector Testers

The most basic type, a pop tester, consists of a hand-operated pump, pressure gauge, and injector mounting fixture. These testers verify opening pressure and spray pattern but provide limited diagnostic information. Despite their simplicity, pop testers remain valuable for checking mechanical injector operation and comparing performance between injectors.

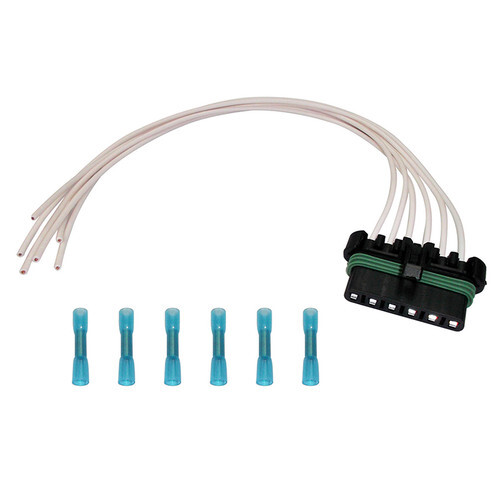

Motorized test benches represent the next level of sophistication. These units use electric pumps to generate consistent pressure, allowing extended testing without manual pumping. They typically include:

- Digital pressure gauges for accurate readings

- Flow measurement capabilities

- Spray pattern visualization chambers

- Return flow measurement systems

- Temperature control for realistic testing conditions

Professional computerized testers offer the most comprehensive analysis. These systems can simulate engine operating conditions, measure injection timing, analyze spray patterns using high-speed cameras, and generate detailed performance reports. While expensive, they provide invaluable data for diagnosing complex injector issues.

Setting Up and Operating the Tester

Proper setup ensures accurate, safe testing. Begin by thoroughly cleaning the injector exterior to prevent contamination during testing. Install the appropriate adapter for your injector type, ensuring all connections are secure. Different injector designs require specific adapters, so having a complete set is essential for testing various engines.

Fill the tester with clean test fluid (specialized calibration fluid or clean diesel fuel). Avoid using old or contaminated fuel, as this can affect results and potentially damage the tester. Prime the system to remove all air, as trapped air creates erratic pressure readings and prevents accurate flow measurement.

Mount the injector securely in the test fixture, connecting fuel supply and return lines as applicable. For common rail injectors, ensure electrical connections are properly made if your tester includes electronic control capabilities. Position spray shields or collection containers to safely contain fuel spray during testing.

Interpreting Test Results

Understanding test results requires knowledge of your specific injector's specifications. Key parameters to evaluate include:

Opening pressure indicates when the injector begins spraying fuel. Compare measured values to manufacturer specifications, typically found in service manuals. Variations exceeding 10% usually indicate problems requiring attention. Low opening pressure suggests worn components or weak springs, while excessive pressure might indicate sticking or carbon buildup.

Spray pattern quality reveals internal condition. A proper pattern should be finely atomized, cone-shaped, and symmetrical. Look for: • Even distribution without streaming or dribbling

- Consistent spray angle matching specifications

- No visible fuel droplets (indicating poor atomization)

- Clean cutoff when injection stops

Flow rate testing measures fuel delivery volume over time. Run the test at specified pressure for a set duration (usually 30 seconds to 1 minute), collecting and measuring delivered fuel. Compare results between injectors, as variations exceeding 5% can cause rough running and performance issues.

Leak testing verifies injector sealing. Apply pressure slightly below opening pressure and observe for drips. Properly sealed injectors should show no external leakage and minimal internal leakage (return flow). Excessive leakage indicates worn components requiring replacement rather than cleaning.

Making Decisions Based on Test Results

Test results guide your maintenance approach. Injectors showing pressure variations but good spray patterns often respond well to cleaning. Those with poor patterns despite correct pressure might improve with thorough cleaning, though success isn't guaranteed.

Injectors failing multiple tests typically require rebuilding or replacement. Examples include:

- Opening pressure more than 20% out of specification

- Asymmetrical or streaming spray patterns

- Flow rates varying more than 10% from specifications

- Excessive internal or external leakage

Document all test results before and after cleaning. This creates a performance baseline and validates the effectiveness of your cleaning efforts. Professional shops often provide customers with these test reports, demonstrating the value of their service.

Best Practices for Maintaining Clean Diesel Fuel Injectors

Prevention remains more effective and economical than correction when it comes to injector maintenance. Implementing proper preventive measures can extend injector life significantly, potentially doubling or tripling the interval between major cleaning services.

Fuel Quality and Filtration

Fuel quality directly impacts injector cleanliness. Purchase diesel from high-volume stations where fuel turnover prevents degradation. Avoid stations with visible water in sight gauges or those receiving deliveries (which stir up tank sediment). Consider using fuel test kits to check for water and contamination at questionable sources.

Upgrade your filtration system beyond factory specifications. Installing a quality fuel/water separator provides the first line of defense against contamination. Consider adding:

- Pre-filter systems with water separation

- High-efficiency main filters (2-5 micron rating)

- Filter restriction gauges to monitor condition

- Electric fuel heaters for cold climate operation

Change filters at or before manufacturer intervals. Fuel filters are inexpensive compared to injector repairs. In dusty conditions or with questionable fuel quality, halve the recommended change interval. Always fill new filters with clean diesel before installation to prevent air ingestion.

Regular Additive Use

Consistent use of quality fuel additives provides ongoing cleaning and lubrication. Unlike gasoline, diesel fuel benefits from additional lubricity enhancers, especially ultra-low sulfur formulations. Select additives containing:

- Detergents for deposit control

- Lubricity improvers to reduce wear

- Cetane improvers for better combustion

- Water dispersants to prevent separation

- Stability enhancers for stored fuel

Develop a regular treatment schedule rather than waiting for problems. Many fleet operators add maintenance doses with every fill-up, while others treat every third or fourth tank. Consistency matters more than frequency for preventive maintenance.

Operating Practices

How you operate your diesel significantly impacts injector cleanliness. Extended idling creates ideal conditions for deposit formation, as combustion temperatures remain low and fuel doesn't burn completely. Minimize idle time, using auxiliary power units or shutting down when parked for extended periods.

Ensure engines reach full operating temperature regularly. Short trips where the engine never fully warms promote deposit formation and water accumulation in fuel. When possible, combine short trips or take occasional longer drives to fully heat the system.

Avoid lugging the engine under heavy loads. Operating at very low RPM under load creates excessive cylinder pressures and incomplete combustion. Downshift to maintain RPM within the engine's power band, especially when towing or climbing grades.

Storage and Seasonal Considerations

Diesel fuel degrades during storage, forming gums and varnishes that clog injectors. For seasonal equipment or backup generators, implement proper storage procedures:

- Fill tanks completely to minimize condensation

- Add fuel stabilizer rated for your storage duration

- Run engines monthly to circulate treated fuel

- Consider biocide treatment in humid climates

- Drain water separators before and after storage

For equipment returning to service, replace fuel filters and run a strong dose of injector cleaner through the system before placing under load. This removes deposits formed during storage and prevents injector damage.

Professional vs. DIY Cleaning: Making the Right Choice

Deciding between professional service and DIY cleaning depends on several factors including your mechanical expertise, available tools, and the severity of injector problems. Understanding the advantages and limitations of each approach helps make an informed decision.

When to Choose Professional Service

Professional cleaning becomes necessary when:

- Diagnostic codes indicate electrical issues with injectors

- Multiple injectors show significant flow variations

- You lack specialized tools like injector pullers or testers

- The engine has high mileage with unknown maintenance history

- Warranty considerations require documented service

Professional shops offer advantages including specialized equipment, experienced technicians, and often warranties on their work. They can perform comprehensive testing, identify worn components needing replacement, and have access to updated service information for specific engines.

Cost considerations vary widely based on location and engine type. Common rail injector service typically costs more than mechanical injector work due to complexity. However, professional service often includes:

- Complete system diagnosis

- Ultrasonic cleaning with professional equipment

- Flow testing and calibration

- Replacement of wear components

- Warranty protection

DIY Cleaning Considerations

DIY cleaning makes sense for:

- Preventive maintenance on known-good injectors

- Addressing minor performance issues

- Owners with mechanical experience and proper tools

- Situations where professional service isn't readily available

Success with DIY cleaning requires realistic expectations. While you can achieve good results with chemical cleaning and basic manual methods, matching professional results requires significant tool investment. Consider starting with chemical methods before attempting manual removal and cleaning.

Safety remains paramount when working with diesel fuel systems. High-pressure fuel can cause serious injury, and diesel fuel presents fire hazards. Always:

- Depressurize systems completely before service

- Work in well-ventilated areas

- Keep fire extinguishers readily available

- Wear appropriate protective equipment

- Dispose of waste fuel and cleaners properly

Hybrid Approaches

Many diesel owners find success with hybrid approaches. Examples include:

- Performing regular chemical cleaning yourself while scheduling periodic professional service

- Removing injectors yourself but having them professionally cleaned and tested

- Using professional diagnosis to identify problem injectors, then cleaning them yourself

This balanced approach maximizes value while ensuring critical work receives professional attention. Building relationships with reputable diesel shops provides access to expertise when needed while maintaining control over routine maintenance.

Advanced Injector Cleaning Techniques and Considerations

For those seeking to go beyond basic cleaning methods, several advanced techniques can restore even severely degraded injectors. These methods require additional investment in equipment or materials but can salvage injectors that might otherwise need replacement.

Ultrasonic Cleaning Optimization

While basic ultrasonic cleaning helps, optimizing the process dramatically improves results. Professional techniques include:

Using heated cleaning solutions (140°F to 160°F) to enhance chemical action. Heat increases solvent effectiveness and reduces cleaning time. Purpose-built injector cleaning solutions outperform generic ultrasonic fluids, containing specific detergents for carbon removal.

Varying ultrasonic frequency during cleaning cycles. Some deposits respond better to different frequencies, so units with variable or sweep frequency capabilities provide superior cleaning. Professional machines often combine 28kHz and 40kHz transducers for comprehensive cleaning.

Implementing staged cleaning processes. Rather than one long cycle, use multiple shorter cycles with inspection between stages. This allows removal of loosened deposits and fresh solution exposure to remaining contamination.

Chemical Enhancement Methods

Advanced chemical treatments go beyond standard cleaning solutions. Specialized products for professional use include:

Acidic cleaners for removing rust and corrosion from water contamination. These require careful handling and neutralization but can restore injectors with internal corrosion. Always follow manufacturer guidelines and use appropriate protective equipment.

Enzymatic cleaners that break down biological contamination from diesel bug infestations. These products work slowly but effectively on organic deposits that resist traditional solvents. Treatment may require extended soaking periods.

Two-part cleaning systems using different chemicals for specific deposit types. Initial treatment might focus on carbon removal, followed by a second product addressing varnish or gum deposits. This targeted approach improves overall effectiveness.

Flow Bench Modifications

Standard diesel fuel injector testers can be enhanced for better diagnostic capabilities. Modifications include:

Adding backpressure simulation to replicate exhaust pressure effects on injector operation. This reveals problems not apparent under atmospheric conditions. Simple ball valves can create adjustable backpressure for testing.

Installing high-speed cameras or strobe lights for detailed spray pattern analysis. Recording spray development helps identify subtle problems affecting combustion efficiency. Modern USB microscopes provide affordable visualization options.

Incorporating temperature control for hot testing. Injector behavior changes with temperature, so testing at operating temperature reveals issues masked when cold. Immersion heaters or heated chambers accomplish this.

Rebuilding vs. Cleaning Decisions

Advanced diagnosis helps determine when cleaning alone isn't sufficient. Signs indicating rebuilding needs include:

Visible wear on sealing surfaces observed under magnification. Minor scoring might be polished out, but deep grooves require component replacement. Jeweler's loupes or USB microscopes aid inspection.

Measured specifications outside acceptable ranges despite thorough cleaning. This includes:

- Nozzle hole erosion causing excessive flow

- Valve seat wear preventing proper sealing

- Spring fatigue reducing opening pressure

- Electromagnetic coil degradation in electronic injectors

Cost analysis often favors rebuilding over replacement for expensive injectors. Rebuild kits containing wear components cost fraction of new injectors while restoring original performance.

Common Mistakes to Avoid When Cleaning Diesel Fuel Injectors

Learning from others' mistakes prevents damage and improves results. These common errors can turn simple maintenance into expensive repairs:

Contamination During Service

The smallest contamination can damage precision injector components. Common contamination sources include:

Using dirty tools or work surfaces. Always clean tools thoroughly and work on clean, lint-free surfaces. A speck of dirt in an injector can cause permanent damage. Set up dedicated clean work areas for injector service.

Allowing debris into open fuel lines or injector bores. Cap or tape all openings immediately upon disconnection. Even brief exposure allows contamination entry. Keep supplies of proper-sized caps and plugs readily available.

Reusing single-use components. Copper sealing washers, O-rings, and gaskets compress during initial use. Reusing them virtually guarantees leaks. Always have replacement seal kits before beginning work.

Incorrect Cleaning Product Use

Using wrong cleaning products causes more harm than good:

Applying gasoline or harsh solvents not designed for injector cleaning. These can damage internal seals, remove protective coatings, or leave residues affecting operation. Only use products specifically designed for diesel injector service.

Over-concentrating cleaning additives thinking "more is better." Excessive concentration can:

- Damage fuel system components

- Dislodge deposits too quickly, clogging filters

- Create combustion problems

- Accelerate seal deterioration

Using incompatible chemicals together. Mixing different cleaning products can create dangerous reactions or neutralize cleaning effectiveness. Never combine products unless specifically directed by manufacturers.

Improper Handling and Installation

Physical damage during service ruins injectors:

Forcing stuck injectors without proper tools. Prying or hammering damages both injectors and cylinder heads. Invest in proper pullers or seek professional help for stuck injectors. Patience and penetrating oil work better than force.

Incorrect torque during installation. Under-torquing causes leaks and combustion gas erosion. Over-torquing cracks components or distorts sealing surfaces. Always use torque wrenches and follow specifications exactly.

Mixing up injectors or fuel lines during reassembly. This causes calibration issues and poor performance. Label everything during disassembly and verify correct positioning before final tightening.

Incomplete System Service

Addressing only injectors while ignoring related components limits effectiveness:

Not replacing fuel filters after cleaning. Dislodged deposits often clog filters shortly after cleaning. Always install new filters to protect newly cleaned injectors.

Ignoring fuel supply system issues. Low fuel pressure from weak pumps or restricted lines prevents proper injector operation regardless of cleanliness. Verify entire system health during service.

Skipping critical adjustments. Some engines require valve adjustment or timing verification after injector service. Consult service manuals for complete procedures.

Frequently Asked Questions (FAQ)

How often should I clean my diesel fuel injectors?

The frequency of cleaning diesel fuel injectors depends on several factors including fuel quality, operating conditions, and maintenance history. For preventive maintenance, most diesel engines benefit from chemical cleaning every 15,000 to 30,000 miles. Heavy-duty applications or engines using questionable fuel may need more frequent service. Manual cleaning typically isn't necessary until performance problems develop or at major service intervals (100,000+ miles). Watch for symptoms like rough idle, decreased fuel economy, or excessive smoke as indicators that cleaning is needed regardless of mileage.

Can I use gasoline injector cleaner in my diesel engine?

No, gasoline injector cleaners should never be used in diesel engines. Diesel fuel systems operate at much higher pressures and temperatures than gasoline systems, requiring specially formulated cleaners. Gasoline cleaners may damage diesel injection components, lack necessary lubricity enhancers, and fail to address diesel-specific deposits. Always use cleaning products specifically labeled for diesel engines. Quality diesel cleaners contain appropriate detergents, lubricity additives, and cetane improvers designed for diesel fuel characteristics.

What's the difference between mechanical and electronic diesel injector cleaning?

Mechanical injectors (pre-common rail) are purely pressure-activated devices that can be disassembled and cleaned thoroughly. Electronic injectors used in common rail systems contain precise electromagnetic valves and sensors requiring specialized equipment for proper service. While both benefit from ultrasonic cleaning and chemical treatments, electronic injectors often need professional testing equipment to verify solenoid operation and calibration. Electronic injectors also require careful handling to avoid damaging delicate internal components and electrical connections.

How do I know if my injectors need cleaning or replacement?

A diesel fuel injector tester provides definitive answers by measuring opening pressure, spray pattern, flow rate, and sealing ability. Injectors showing pressure within 10% of specifications with good spray patterns typically respond well to cleaning. Those with asymmetrical patterns, excessive leakage, or pressure variations exceeding 20% often need rebuilding or replacement. Visual inspection revealing external damage, severe corrosion, or worn nozzle tips indicates replacement is necessary. When in doubt, professional testing provides accurate assessment.

Is it worth investing in a diesel fuel injector tester for DIY use?

For diesel owners maintaining multiple vehicles or equipment, a basic pop tester ($200-$500) provides valuable diagnostic capability and pays for itself quickly. Single vehicle owners might find chemical cleaning and professional testing when needed more economical. Consider factors like mechanical aptitude, frequency of use, and types of engines serviced. Even basic testers help verify cleaning effectiveness and identify problem injectors, making them valuable diagnostic tools for serious DIY mechanics.

Can ultrasonic cleaning damage diesel injectors?

When used properly, ultrasonic cleaning is safe and effective for diesel injectors. However, excessive time, temperature, or frequency can potentially damage components. Follow these guidelines: limit cleaning cycles to 10-15 minutes, maintain solution temperature below 160°F, use appropriate cleaning solutions, and avoid ultrasonic cleaning of electronic components. Professional-grade equipment with proper settings poses minimal risk. The benefits of thorough cleaning far outweigh potential risks when procedures are followed correctly.

What causes diesel injector failure besides contamination?

While contamination represents the primary cause, other factors contribute to injector failure including normal wear from high-pressure operation, poor fuel lubricity in ultra-low sulfur diesel, water damage causing internal corrosion, overheating from cooling system problems, and electrical issues in electronic injectors. Manufacturing defects, though rare, can cause premature failure. Extended idling accelerates wear by creating incomplete combustion and deposit formation. Using quality fuel, maintaining proper cooling system operation, and following service intervals prevents most non-contamination failures.

Should I clean all injectors even if only one shows problems?

Yes, cleaning all injectors simultaneously is recommended for several reasons. Labor represents the major cost for professional service, making complete service economical. All injectors experience similar conditions and contamination levels. Flow variations between clean and dirty injectors cause performance issues. Age-related wear affects all injectors similarly. Preventive maintenance on functioning injectors extends their service life. The minimal additional cost of cleaning all injectors provides peace of mind and consistent performance.

How long do cleaned diesel injectors typically last?

Properly cleaned injectors can provide another 50,000 to 100,000 miles of service, depending on fuel quality and maintenance practices. Engines using clean fuel with regular additive treatment see longer intervals between cleaning. Those exposed to water contamination, poor fuel, or excessive idling require more frequent service. Implementing preventive measures like quality filtration and fuel additives significantly extends cleaning intervals. Professional rebuilding with new components often provides like-new longevity.

What's the most cost-effective approach to diesel injector maintenance?

The most economical strategy combines preventive chemical maintenance with periodic professional service. Use quality fuel additives regularly (adding $5-10 per tank), change fuel filters on schedule ($50-100), and perform direct injection cleaning annually or bi-annually ($150-300). This prevents major problems requiring expensive manual cleaning or replacement. When professional service becomes necessary, address all injectors simultaneously. This approach typically costs less than one injector replacement while maintaining optimal performance. Remanufactured injectors offer excellent value when replacement becomes necessary, providing new-injector performance at significant savings.