How Does a Turbo Work on a Diesel Engine?

Apr 11th 2022

If you own a modern diesel engine, your vehicle uses what’s known as a turbocharger. Virtually all modern diesel engines use this technology. The turbo compresses air as it goes into the combustion chamber, which increases engine power and performance. This component has become a staple of the diesel industry. Drivers have come to depend on the extra power that comes with turbos, but many still don’t understand how they work. Learn more about how turbos work on diesel engines and what happens when things go wrong.

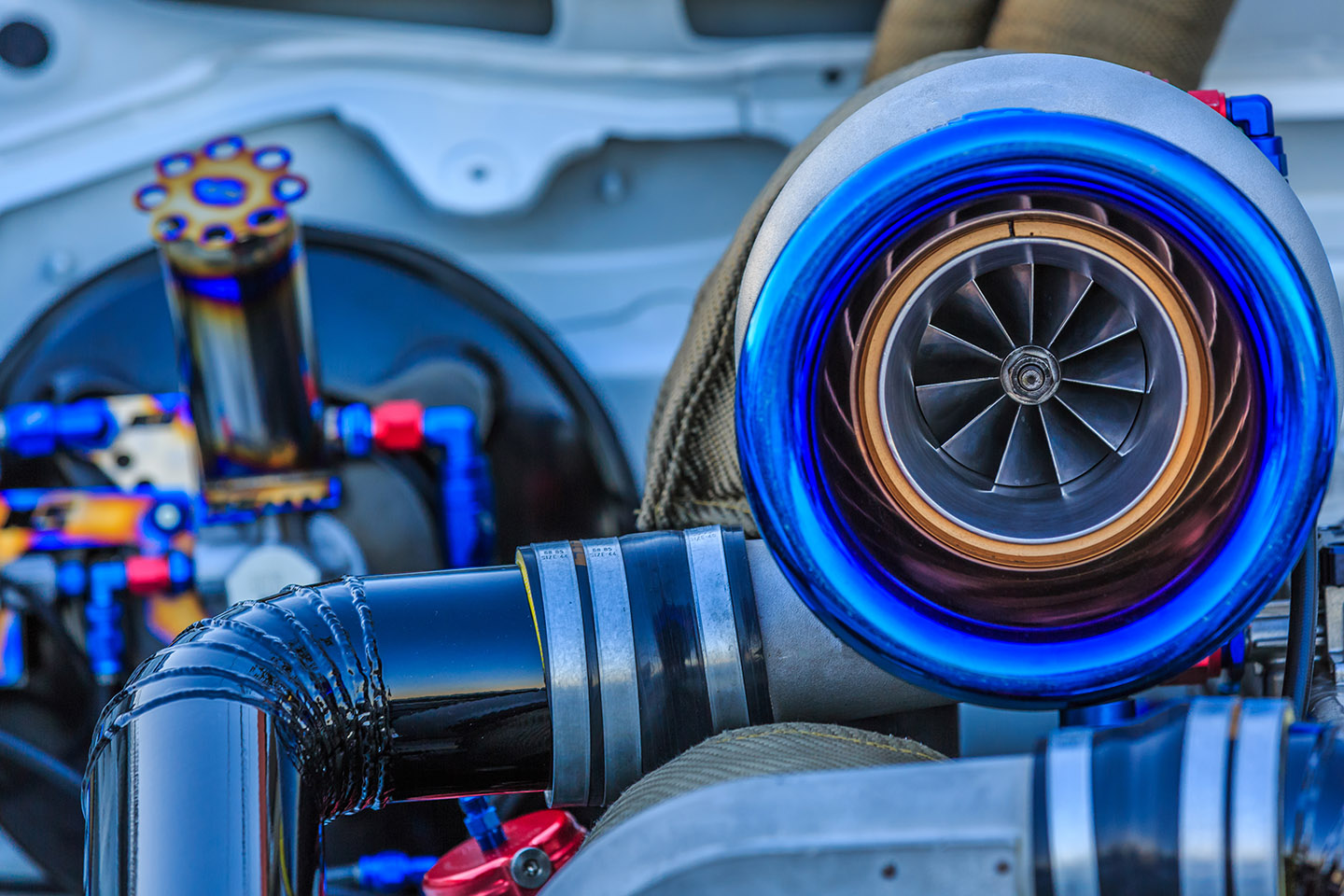

What Is a Turbocharger on a Diesel Engine?

The turbocharger is designed to increase the amount of air going into the combustion chamber, which gives the engine a boost.

All diesel engines need air and fuel to power the engine. Naturally aspirated diesel engines use ambient air around the engine. The piston moves down, which allows air to pass naturally into the combustion chamber. They have a simple design, but they can only do so much to increase the amount of air going into the chamber.

Turbocharged diesel engines suck in additional air to increase engine power. The more air that enters the engine, the faster the fuel will burn, which generates additional power. There’s typically a slight delay from the time you engage the turbo to when you feel the boost. This is what’s known as turbo lag. The system needs several seconds or more to properly compress the additional air that’s going into the combustion chamber.

So, how does a turbocharger work?

Once the air leaves the combustion chamber, it enters the turbine housing and moves the turbine wheel. The energy generated from the turbine wheel powers the compressor, which increases air pressure while reducing the velocity. The air then passes through an exhaust outlet before re-entering the combustion chamber.

Turbos can either be manual, automatic or a combination of the two. Automatic turbos will adjust the amount of air coming into the combustion chamber based on how much horsepower is needed to move the vehicle. Manual turbos give you more control. You can rev up the turbo whenever you need a boost. Hybrid systems let you turn the automatic functions on and off.

When you power up the turbo, you send a signal to the engine that you need to increase power. This requires additional air and fuel. Stepping on the gas will send more fuel into the combustion chamber as the turbo increases the amount of air. This increases the amount of exhaust gas, which then keeps the turbo moving.

Turbos are largely responsible for making sure there is the right amount of air in the combustion chamber. If there is too much air in the chamber, the exhaust gas will run hotter than normal. You will start to burn through more fuel than necessary as your aftertreatment cooling system works to reduce the temperature.

Using the turbo increases the flow of fuel, which puts extra pressure on your diesel particulate filters. These filters are designed to get rid of particles that can damage your engine components. Remember to replace your diesel particulate filters as needed to reduce wear and tear.

Shop Diesel Particulate Filters Online

Fixed vs. Variable Geometry Turbos

Diesel engines use either fixed or variable geometry turbos.

In a fixed geometry turbo, the turbine and compressor have set geometries. The flow of compressed air depends on the flow of exhaust gas. This means the turbo will either speed up or cool down based on operating conditions. They have a simple design and are relatively easy to maintain. Fixed geometry turbos are typically used in vehicles that maintain steady airflows, as the geometry cannot be changed.

Variable geometry turbos (VGT) can adjust the geometries of the turbine and compressor based on driving conditions. The exhaust gas enters a series of sliding vanes. The turbo actuator will change the shape of these vanes to adjust the flow of exhaust gas going into the compressor. VGTs can help improve fuel efficiency by limiting the amount of air entering the combustion chamber.

Problems with the Turbocharger

Diesel engines rely on large quantities of oil to improve lubrication. They generate immense heat and pressure, and the oil coats the various mechanical components in a protective layer to prevent rust and grind. If your engine doesn’t have enough oil or is using dirty oil, the turbocharger will be one of the first to go.

The turbo relies on oil to power the compressor, which sends compressed air into the combustion chamber. Without enough oil, these parts will eventually wear down and break apart. Needlessly engaging the turbo can also overwhelm these parts. They may crack or fail if the pressure becomes too much. Using poor quality oil can also clog the turbo, reducing the flow of exhaust gasses, which cuts off power to the engine.

A piece of debris or foreign object could also clog your turbo. Gravel, rocks and other particulate matter can slip inside your air intake valve, wreaking havoc on the turbocharger.

The turbo is only as healthy as the air passing through it. The diesel particulate filter (DPF) is designed to remove excess particulate matter from the exhaust gas before it gets recycled back into the combustion chamber. Removing soot, ash, and other materials that are created during the burning process will keep the turbo clean. If the DPFs are clogged with too much material, less air will be able to reach the engine. Be sure to clean and/or replace your DPFs on a regular basis to improve airflow.

If you recently replaced your turbo and are still having problems, it may not have been installed properly. Leaks and gaps between the turbo and turbo housing will reduce the amount of air going into the combustion chamber. Holes or leaks in the engine’s air intake valve can cause these problems as well. It’s all about making sure the engine has a steady stream of clean, compressed air.

Symptoms of a Bad Turbocharger

A faulty turbocharger can lead to a range of problems behind the wheel. If the air-gas ratio is off, fuel economy will plummet. You may also see a sudden drop in engine power and/or acceleration. Horsepower may suffer as a result as well, which can limit the engine’s ability to tow heavy loads at low RPMs. If the problem persists, watch out for blue or gray smoke coming out of the exhaust and excessive noise.

You may need to replace your turbo actuators as you continue using turbo. The actuators run on electricity. If the system fails, the sliding vanes will default to 100 percent open. This will increase the amount of compressed air going into the chamber, which can decrease fuel efficiency.

The actuator on the 6.0 Powerstroke has been particularly problematic. Find replacement 6.0 VGT actuators online to improve engine performance.

Image Credits

Sherbak_photo /Shutterstock.com

Avigator Fortuner /Shutterstock.com

Comedstock /Shutterstock.com