What’s a Temporary Fix for a Crankshaft Position Sensor?

Mar 20th 2023

notsuperstar/shutterstock.com

Diesel engines are sophisticated machines that run on various sensors and electrical inputs. The timing and pace of the fuel injection process must be in sync with the motion of the wheels to keep the vehicle running at the required speed. The crankshaft position sensor is required to complete this essential process. It sends information about the crankshaft to the engine control unit, so it can adjust the timing of the injectors accordingly. If you are running on a bad crankshaft position sensor, use this guide to find a temporary solution to the problem.

What Is a Crankshaft Position Sensor?

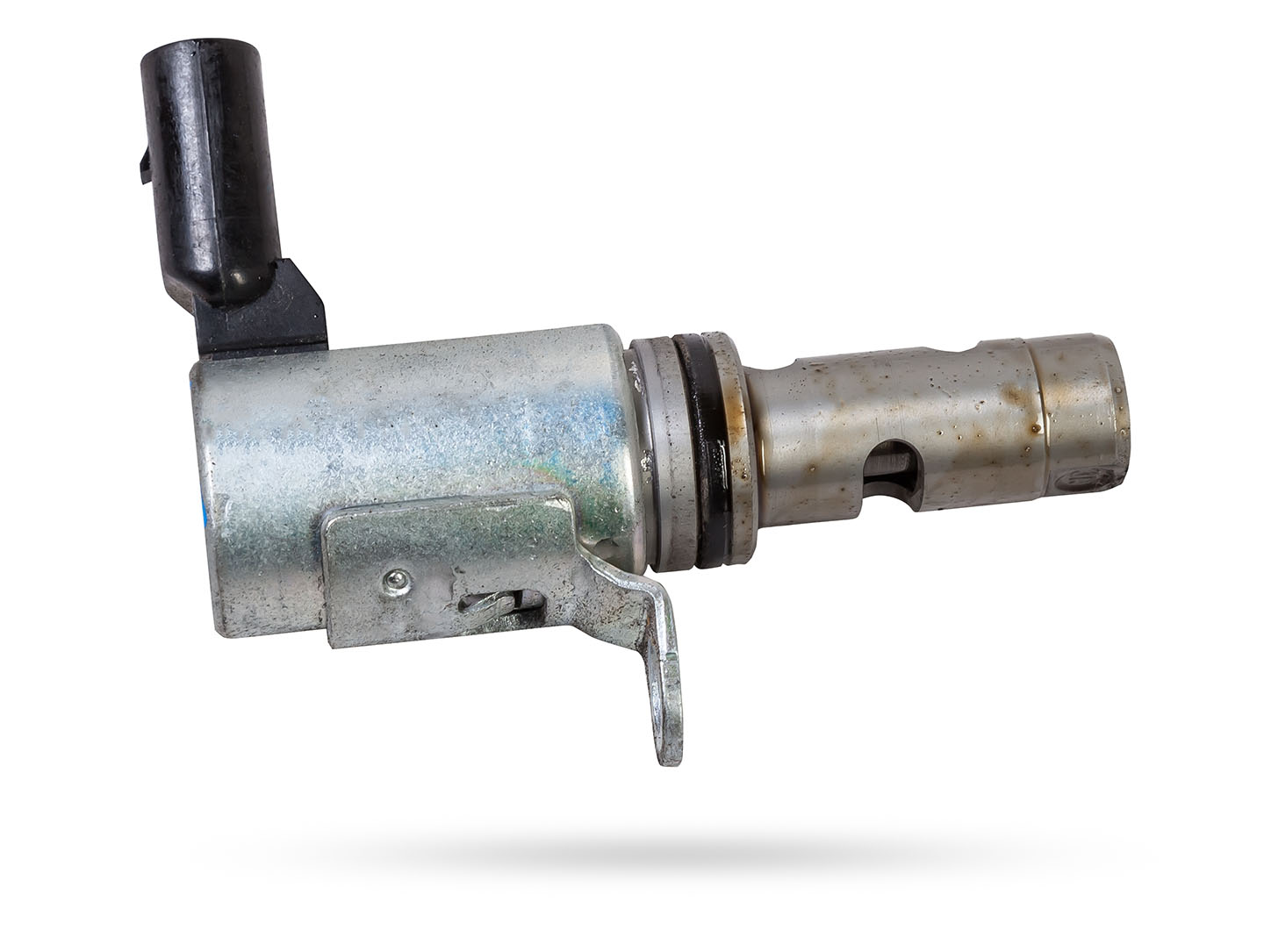

The energy generated through internal combustion is sent to the wheels, which then move the vehicle forward. The crankshaft is responsible for converting the motion of the piston to the rotation of the wheel shaft. The crankshaft position sensor monitors the rotational speed of the crankshaft. It then sends this information to the engine control unit, which adjusts virtually every other aspect of the engine, including the timing of the fuel injection, how long the fuel is burned, cooling, and exhaust.

Without a working crankshaft position sensor, the engine would essentially be driving blind with no idea how the energy created is being used. The location of the sensor largely depends on the make and model of the vehicle. It is usually bolted to the casing of the crankshaft, cylinder head, or engine valve cover.

Velimir Zeland/shutterstock.com

How Do I Know if the Crankshaft Position Sensor Is Bad?

A faulty sensor will lead to various issues behind the wheel. It is susceptible to extreme heat and gradual desensitization just like any other sensor. Excess wear and tear and a bad cooling system will cause the sensor to shut down. The device will also gradually become less accurate over time, especially if you use the vehicle for shorter trips.

If the sensor fails entirely, the check engine light should come on. You may also have trouble starting the vehicle. The engine will also have trouble calculating power based on the speed of the vehicle, which can lead to stalling and sudden surges/reductions in power. You can try idling to see if the engine can handle sitting still for too long. Watch out for poor fuel efficiency as your vehicle burns through more than necessary. The problem tends to happen more often in older diesel engines. If you have been using the same make and model for a while or bought the vehicle used, find out how long diesel engines lastto get a sense of their condition.

Shop All of Our Diesel Products

Aleksandr Kondratov/shutterstock.com

Quick Fix for a Bad Crankshaft Position Sensor

Considering you might have trouble starting your truck with a bad crankshaft position sensor, you should head to the nearest mechanic or back to the service site for immediate repairs, so you don’t get stranded on a run. You might have to deal with the problem yourself in a dire situation. It’s best to replace the crankshaft and crankshaft position sensor as soon as possible once it fails.

Check the engine light error code to see if the crankshaft position sensor is the problem. The engine will likely be overheated, so pull over to a safe area, come to a stop, and turn the engine off. Let it rest and cool down for a few minutes before starting it again. The wheels might not be getting enough power now that the engine control unit isn’t in control. Try fueling up to increase the amount of fuel being injected into the combustion chamber. You can also try disconnecting the sensor altogether and restarting the engine, which could set the control unit to default. That should be enough to get you home, but there is a chance your vehicle may not start at all.

This isn’t designed to be a permanent solution to the problem, as driving without a working sensor can be dangerous. If you ignore the problems listed above and let the sensor continue to decline, it’s only a matter of time before the engine won’t start. The crankshaft position sensor is an essential, although often overlooked, part of any diesel truck. Keep these tips in mind to assess the problem without further damaging the engine.