Most Common EGR Failure Modes and Testing Procedures

Sep 30th 2025

Table of Contents

- Introduction to EGR Systems

- Why EGR Components Fail

- Essential Diagnostic Toolkit

- Most Common EGR Failure Modes

- Step by Step Testing Workflow

- EGR Issues and Aftertreatment Interactions

- Preventive Practices for Longer EGR Life

- Pass or Fail Quick Reference Guide

- Frequently Asked Questions

- Conclusion

Introduction to EGR Systems

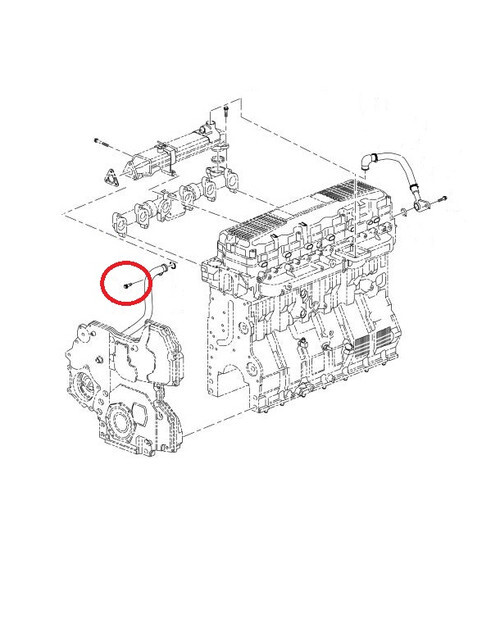

The Exhaust Gas Recirculation system is a core emissions technology that reduces nitrogen oxide formation by redirecting exhaust gas back into the intake. Although the concept is simple, the execution involves coolers, valves, bypasses, sensors, and complex control logic.

When an EGR component fails, performance declines, emissions rise, and serious mechanical damage can occur. Understanding how failures occur and applying proper tests is essential for accurate repair and long-term reliability.

Why EGR Components Fail

EGR systems endure punishing conditions. Factors include:

- Constant thermal cycling that weakens metals and joints

- Acidic exhaust exposure that corrodes internal surfaces

- Heavy soot and hydrocarbon deposits that clog passages

- Engine vibration that stresses welds and brackets

- Electrical harness fatigue that disrupts control signals

- Coolant chemistry errors that accelerate corrosion

Failures often overlap. A cooler leak may coincide with sensor drift or valve malfunction. Correct testing is the only way to separate symptoms from the root cause.

Essential Diagnostic Toolkit

Technicians need a comprehensive toolkit to pinpoint faults. Critical tools include:

- Scan tool with bidirectional capability to command EGR operation and log MAF, MAP, and EGR data

- Cooling system pressure tester with proper adapters

- Block test kit for combustion gas in coolant

- Low pressure regulated air source for cooler testing

- Smoke machine to find intake or exhaust leaks

- Infrared thermometer or thermocouples for cooler delta checks

- Borescope for internal inspection

- Hand vacuum pump for vacuum actuated valves

- Multimeter or scope for sensor and circuit testing

These tools turn uncertain guesses into precise conclusions.

Most Common EGR Failure Modes

Internal EGR Cooler Leaks

Symptoms: Unexplained coolant loss, white steam from exhaust, pressurized degas bottle, or misfires at startup.

Testing: Pressure test cooling system, perform block test, isolate cooler and submerge with pressurized air, check temperature delta across cooler.

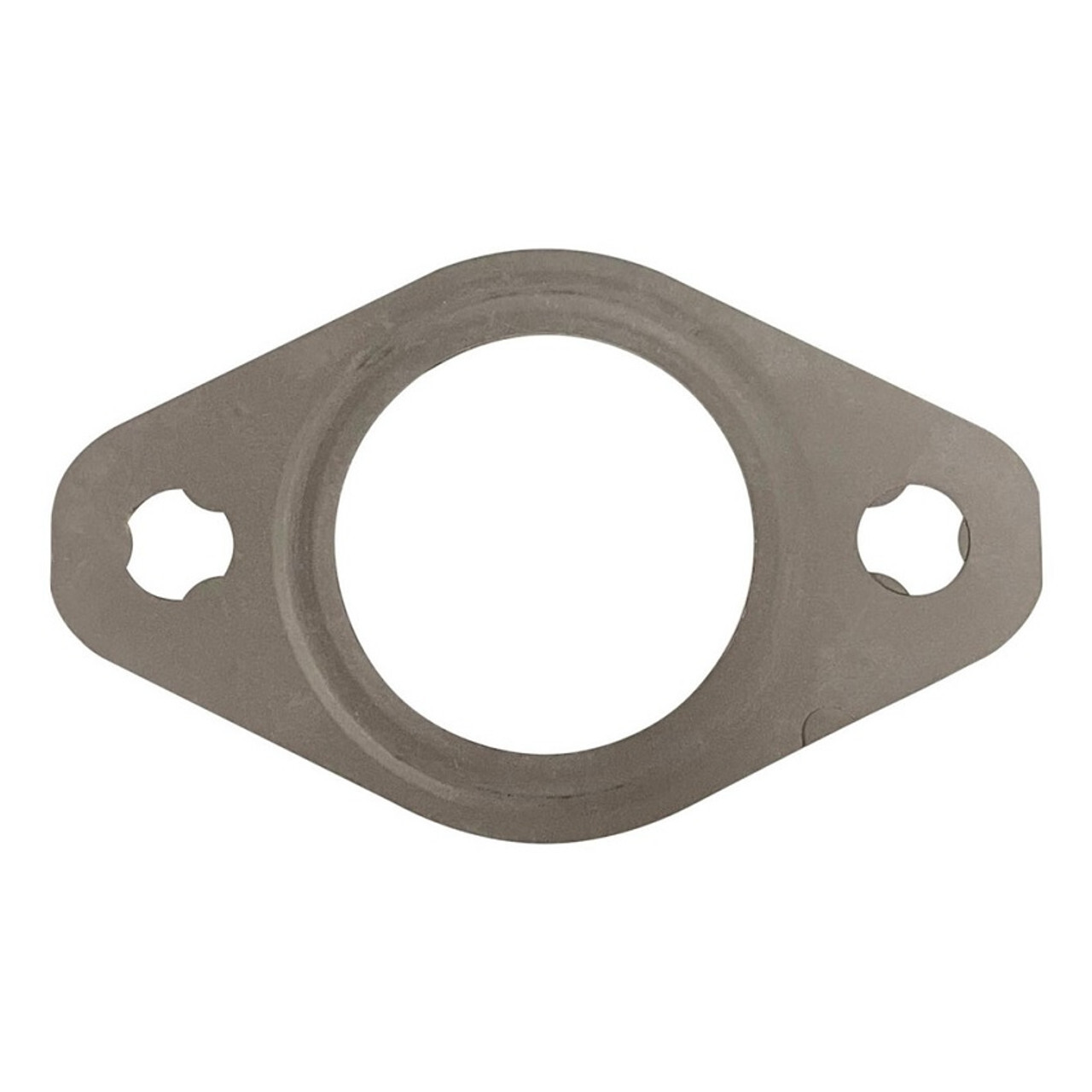

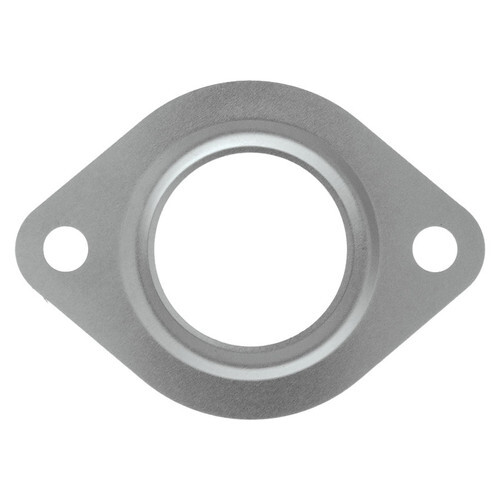

Repair: Replace the cooler, flush and refill coolant, bleed system, and recheck levels. Many owners choose stainless steel remanufactured options like Bostech Cummins 6.7L Cooler with Gasket Kit.

External EGR Cooler Leaks

Symptoms: Coolant smell, crusty residue on cooler body, or dampness under pressure.

Testing: Cooling system pressure test, visual inspection, UV dye in coolant for trace leaks.

Repair: Replace cooler or leaking end tank, reseal joints, torque clamps correctly.

Soot and Ash Restriction

Symptoms: Insufficient flow codes such as P0401, poor response when commanding EGR, frequent DPF regenerations.

Testing: Command EGR and watch MAF and MAP response, check cooler inlet and outlet temps, perform airflow bench test, inspect with borescope.

Repair: Replace cooler and clean adjoining passages. Cleaning attempts rarely restore full function.

EGR Valve Stuck Open

Symptoms: Rough idle, stalling at deceleration, black smoke, poor throttle response, P0402 codes.

Testing: Command valve closed and monitor MAF and MAP, block EGR flow momentarily to see if idle improves, inspect valve internals.

Repair: Replace valve and seals, clean passages, recalibrate if required.

EGR Valve Stuck Closed

Symptoms: Cold start knock, high NOx, insufficient flow codes, slow warm up.

Testing: Command valve open at idle and confirm MAF drop, check vacuum source or actuator movement, compare position feedback to command.

Repair: Replace valve, repair vacuum or electrical circuits, confirm response at idle and part load.

Differential Pressure Sensor Failure

Symptoms: Flat or erratic readings, intermittent codes, weak EGR control.

Testing: Inspect and clear sense tubes, bench test sensor scaling, confirm zero reference key on engine off.

Repair: Replace sensor and tubes, verify dynamic response.

Temperature Sensor Drift or Failure

Symptoms: Incorrect reported temps, false enable or disable of EGR, efficiency codes, derates.

Testing: Compare cold soak readings to ambient, bench test resistance versus temperature, wiggle harness for dropouts.

Repair: Replace sensor, secure wiring, confirm accurate temp tracking.

Bypass Valve or Thermostat Malfunctions

Symptoms: Poor warm up, erratic EGR flow, temp dependent codes.

Testing: Command bypass open and closed, observe thermal response, bench test actuator travel.

Repair: Replace actuator or flap assembly, verify full range motion, recalibrate if platform requires it.

Corrosion and Thermal Fatigue

Symptoms: Repeat cooler failures, debris in coolant, premature leaks.

Testing: Check coolant chemistry and conductivity, inspect failed cores for fracture patterns, verify grounding straps.

Repair: Correct coolant chemistry, flush system, install stainless or updated design coolers such as Bostech Cummins ISL Heavy Duty Cooler.

Control Side and Vacuum Faults

Symptoms: Intermittent EGR response, random codes under vibration or heat, inconsistent actuation.

Testing: Inspect harness for rub through or corrosion, perform voltage drop tests, scope command and feedback signals, substitute known good solenoid if possible.

Repair: Repair harness, replace solenoid, reroute wiring, confirm stable actuation after repair.

Step by Step Testing Workflow

- Capture complaints and diagnostic codes with freeze frames.

- Inspect coolant levels, visible leaks, connectors, hoses.

- Pressure test cooling system and monitor decay.

- Use block tester to detect combustion gas in coolant.

- Command EGR open and closed at idle and check MAF, MAP, and pressure readings.

- Test flow at part load with incremental commands.

- Smoke test intake and EGR piping, borescope cooler passages.

- Remove and isolate cooler for submerged pressure test if suspected.

- Bench test sensors, verify supply and grounds.

Replace failed components, recalibrate, retest, and road test for validation.

EGR Issues and Aftertreatment Interactions

Low EGR flow raises combustion temps and NOx output, forcing SCR systems to compensate. Excess EGR flow increases soot generation and loads the DPF prematurely. Sensor errors confuse PCM logic, leading to unnecessary derates or limp mode. Always stabilize EGR before chasing downstream catalyst or DPF efficiency codes.

Preventive Practices for Longer EGR Life

- Maintain coolant chemistry with OEM approved additives

- Change coolant at proper intervals to prevent internal corrosion

- Keep crankcase ventilation system healthy to limit oil mist and deposits

- Perform software updates that improve EGR control strategies

- Secure harnesses and connectors away from hot zones

- Inspect systems annually or during coolant service for early warning signs

Pass or Fail Quick Reference Guide

|

Test |

Pass Condition |

Fail Condition |

|

Command at idle |

Clear MAF drop or MAP rise |

No change suggests restriction or valve fault |

|

Cooler pressure test |

Holds 15 psi without bubbles |

Any bubbling reveals internal leak |

|

Block test |

No color change |

Color change proves combustion gases in coolant |

|

Sensor zero reference |

Reads baseline within spec |

Offset or unstable reading indicates failure |

|

Valve feedback |

Tracks command closely |

Lagging or flat output indicates fault |

Frequently Asked Questions

A: Light deposits may clean temporarily, but most restrictions require replacement. Deep soot embedding resists cleaning.

A: Perform pressure decay and block tests. Isolate the cooler. If coolant holds with the cooler bypassed, the cooler is at fault.

A: Exhaust gases at idle displace oxygen beyond stable combustion limits, causing roughness or stalling.

A: Differential pressure sensors and temperature sensors, since they influence flow calculations directly.

A: Yes, stainless resists corrosion better than mild steel and is less prone to cracking. Many Bostech heavy duty coolers use stainless tubing for longevity.

Conclusion

EGR systems fail in varied ways: leaks, restrictions, sensor drift, or wiring faults. Accurate testing with the proper toolkit confirms the true cause. Repairs should use high quality replacement parts, such as remanufactured Bostech coolers and valves, combined with careful installation and calibration. Preventive maintenance such as coolant care, proper ventilation, and wiring inspection extends system life.

By understanding common failure modes and applying a structured workflow, technicians and fleets reduce downtime, lower repair costs, and restore compliance and performance with confidence.