Is There a Difference Between a Diesel Mechanic & Engineer?

Jan 7th 2025

Diesel engineers and mechanics are essential players in the transportation and energy supply chains. Their contributions stand on opposite sides of the equation, with the former designing engines and power makers and the latter maintaining these systems once they’re in circulation.

You can turn your love of diesels into a fulfilling, lucrative career as either a mechanic or engineer, depending on your interests, career goals and existing knowledge. Learn what distinguishes a diesel mechanic from an engineer, including the expected responsibilities, salary and certification requirements.

What Is a Diesel Mechanic?

The main objective of any diesel mechanic is to keep the employer’s or customer’s equipment running. They troubleshoot malfunctioning vehicles, generators and fuel systems when problems arise and perform preventative maintenance to limit repairs and downtime. Mechanics work at consumer auto shops, including those that service diesel and gasoline engines, and transportation and energy providers working on company assets. The main goal is to keep the engine running as long as possible, increase efficiency and safety or analyze the cost of repairs and replacements so the manager can make an informed decision.

These professionals are the leading authorities in fixing diesel engines. When drivers hear a strange sound under the hood or suddenly lose power when towing, they will likely visit a mechanic, not an engineer. The mechanic will use diagnostic equipment to detect the problem and can take the engine apart to make the necessary replacements and repairs before putting it back together again.

Mechanics can work a fleet of vehicles or offer their services to the public. An internal mechanic working on company property may focus on a particular make/model or whatever equipment the employer owns. An external mechanic at a shop will benefit from learning a wide range of engine types, including those popular with drivers and companies in the area. If a customer brings a make/model into the shop outside the mechanic’s purview, the mechanic will either learn it on the spot or refer them to someone with the required skills.

Mastering a diesel engine as a mechanic requires an intimate knowledge of the inner workings, including the fuel, exhaust, oil, coolant, steering and electrical systems; the problems they encounter and how to resolve them. Unlike gas engines, diesels use extreme pressure, heat and mechanical components controlled by sensors to ignite fuel. Pressure determines efficiency, with clogs and leaks sapping fuel economy, delaying acceleration and reducing power. They use fuel injectors, one per cylinder, to compress the fuel so it enters the combustion chamber as a fine mist and ignites upon release.

Diesels need more frequent oil changes than their gasoline counterparts to increase lubrication during pressurization. Metal shavings from worn pistons and gears congest passageways, preventing fuel flow.

From passengers on buses to packages and raw materials on trucks bound for warehouses, diesel engines were made to tow. Compressing air and fuel provides the torque needed to move tens of thousands of pounds from rest. Heavy loads strain the fuel, exhaust, oil and coolant systems as output increases. Excess pressure caused by high temperatures can cause the coolant pump to blow, leaking fluid into the crankcase. Replacing the water pump for the car before failure prevents overheating and additional damage.

Environmental regulations introduced emissions requirements to reduce pollution. Vehicles manufactured in the last 20 years use various reduction methods to limit the spread of CO2, including exhaust gas recirculation and selective catalytic reductions that can cause other problems.

Once the mechanic solves the problem, they prescribe a regimen to improve performance and prevent breakdowns, such as recommending service intervals, fuel additives and other products that can improve efficiency and reduce wear and tear. For example, you’ll need to learn the difference between biodiesel vs. diesel and how they affect engines.

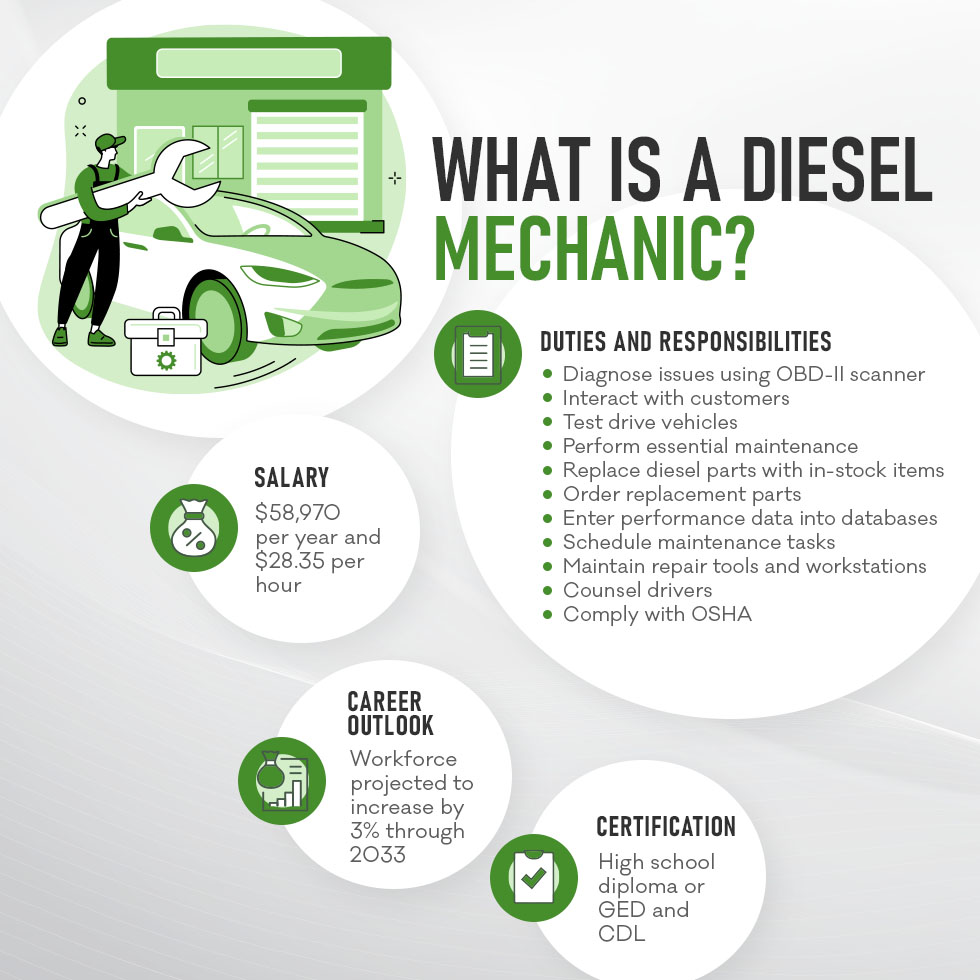

Duties and Responsibilities

Mechanics perform different tasks than engineers, working more with their hands and tools and less with computers. Responsibilities vary based on the types of vehicles being repaired, who owns the equipment and the services offered. Generally, the job requires them to:

- Diagnose sounds, odors and various performance issues using an OBD-II scanner and their technical experience

- Interact with customers, answer questions and explain complex processes clearly

- Test drive vehicles to ascertain performance

- Perform essential maintenance, including oil changes, filter replacements, etc.

- Replace diesel parts with in-stock items

- Order replacement parts online and follow up with vendors

- Enter performance data into databases and customer logs

- Schedule urgent and preventative maintenance tasks based on vehicle availability

- Clean and maintain repair tools and workstations

- Follow instructions in the owner’s manuals

- Counsel drivers on proper driving habits and maintenance routines

- Research and comply with state emissions requirements to help drivers pass inspection

- Comply with OSHA safety requirements and use equipment, including goggles, gloves, knee pads and padded creepers, to reduce the risk of injury.

Salary Expectations

As per the Bureau of Labor Statistics, the median pay for diesel mechanics in 2023 was $58,970 per year and $28.35 per hour, with salaries ranging from $39,020 for the lowest 10 percent and more than $82,430 for the top 10 percent. Compensation depends on location, industry and the type of vehicles serviced. Some also receive a commission or complete jobs under the table.

Career Outlook

Diesel engines provide most domestic freight transportation in the U.S., with trucks delivering 72 percent by value and 64 percent by weight. The need to transport goods will only increase in the years ahead. Auto manufacturers are expected to introduce more efficient models into the market, and existing vehicles will need repairs for decades.

Quality auto technicians are always in demand. According to the BLS, the national mechanic workforce is projected to increase by three percent through 2033, which is on par with the rest of the labor market. New positions will open to support the nation’s increasing dependence on freight trucking. With an average age of 42, many mechanics will likely retire within the decade.

Businesses across industries and organizations use diesel vehicles, including various government agencies, hospitals, construction crews, utilities and moving companies, and all will continue to need licensed mechanics.

Being a mechanic gives you the option of starting your own business. Once you master the most common makes/models, you can set up a garage and hire mechanics as more customers come through. You’ll need to stock the shop with diesel parts to complete jobs quickly and know where to find the ones you don’t have on hand.

Certification

You will likely need a high school diploma or GED to get hired as a diesel mechanic, although it’s possible to land a job without one as long as you demonstrate competence, work hard and learn fast. Taking a postsecondary diesel mechanic training course will instill the required knowledge. You can then work as a trainee in a shop following instructions until you become a junior-level technician, which can take up to four years. You’ll also need a commercial driver’s license (CDL) to operate the vehicles you’ll be working on, which includes passing a driving test, written exam, and physical from the National Registry of Certified Medical Examiners.

Once you’ve worked for two years, you can get certified with the National Institute for Automotive Service Excellence (ASE) to prove your skills to potential employers. You must pass and retake the exam every five years to stay certified.

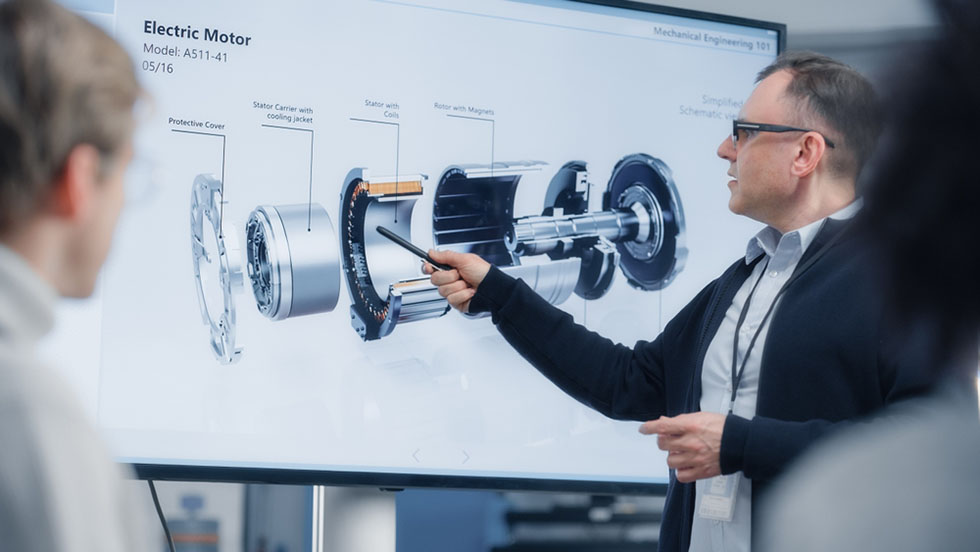

What Is a Diesel Engineer?

Diesel engineers work on the design and production of automobiles, in many cases before they’re available to consumers. They use computer systems and engineering software to create more powerful, efficient engines while weighing other factors such as size, cost, safety, emissions regulations and driveability. Some engineers spend most of their time behind screens analyzing data and building 3-D digital schematics assembled by machines and workers in the production line; others are more hands-on, constructing and taking apart engines already in service.

Before a new model is released, engineers complete extensive tests on newly constructed vehicles for quality assurance and safety. They also revise their designs if the vehicle is recalled or problems are detected.

Fleet owners also retain diesel engineers to improve efficiency and extend the working life of their equipment. Those outside production may oversee mechanics by inspecting their work or creating maintenance guidelines.

Duties and Responsibilities

The average day varies based on the industry and project stage. Those working for a manufacturer will shift from early-stage designing and brainstorming to production oversight before testing the finished product. Overall, engineers may be required to:

- Verify vehicle specifications and calibrations through testing

- Identify market opportunities and develop product ideas based on the competition and driver demand

- Develop maintenance and driving best practices for drivers

- Translate technical processes for marketing or C-suite executives

- Build and reverse-engineer engines and related parts

- Prepare vehicle documentation for stakeholders and regulators

Salary Expectations

Automotive mechanical engineers earned a median of $99,510 annually or $47.84 per hour in 2023. The closer you are to the vehicle’s original inception, the more you stand to earn. The bottom 10 percent earned less than $64,560, and the top 10 percent earned over $157,470.

Career Outlook

Designing a new vehicle involves dozens of skilled engineers. The department is usually hierarchical, with senior engineers delegating tasks to mid- and low-level engineers. You can work your way up by introducing novel ideas that push this technology into the future. Most work full-time jobs with the occasional overtime during rush phases. Demand for mechanical engineers is strong, growing at an expected 11 percent through 2033, much faster than the average occupation.

Certification

You’ll need a high school diploma and a four-year bachelor's degree in mechanical engineering or automotive technology to enter the industry. The curriculum includes chemistry, math and physical sciences. A master’s degree in a related field will make you more attractive to employers. Becoming a licensed engineer or professional engineer (PE) prepares you for a leadership role in the organization, which requires four years of work experience and passing the PE and Fundamentals of Engineering (FE) exams.

Is There a Difference Between a Diesel Mechanic & an Engineer?

Yes, diesel mechanics and engineers lead different lives, with the latter working mainly on production, testing and design and the former working with their hands in garages. These professionals have overlapping knowledge, but engineers have a more in-depth understanding of the mechanical properties of engines and locomotion. However, mechanics are better at completing essential tasks that allow these machines to run. Mechanics also make over half as much as the average engineer, but they have more freedom and flexibility when they work.

How to Choose a Career: Diesel Mechanic vs. Engineer

Both paths will lead you to a satisfying career with good job security, but one means wearing a suit and tie, and the other involves remarkably more grease. Consider your ideal work environment, whether you can afford to attend a four-year college and how soon you want to start working. It’s never too late to go back to school if you change your mind. The skills you learn as a mechanic will inform your education as an engineer. Explore opportunities in your area to begin your journey as a diesel professional.

Image Credits

Net Vector/Shutterstock.com

Gorodenkoff/Shutterstock.com

Gumbariya/Shutterstock.com

BK_graphic/Shutterstock.com

Set Line Vector Icon/Shutterstock.com