How to Depressurize a Fuel System

Feb 6th 2024

Warut Wetsanarut/shutterstock

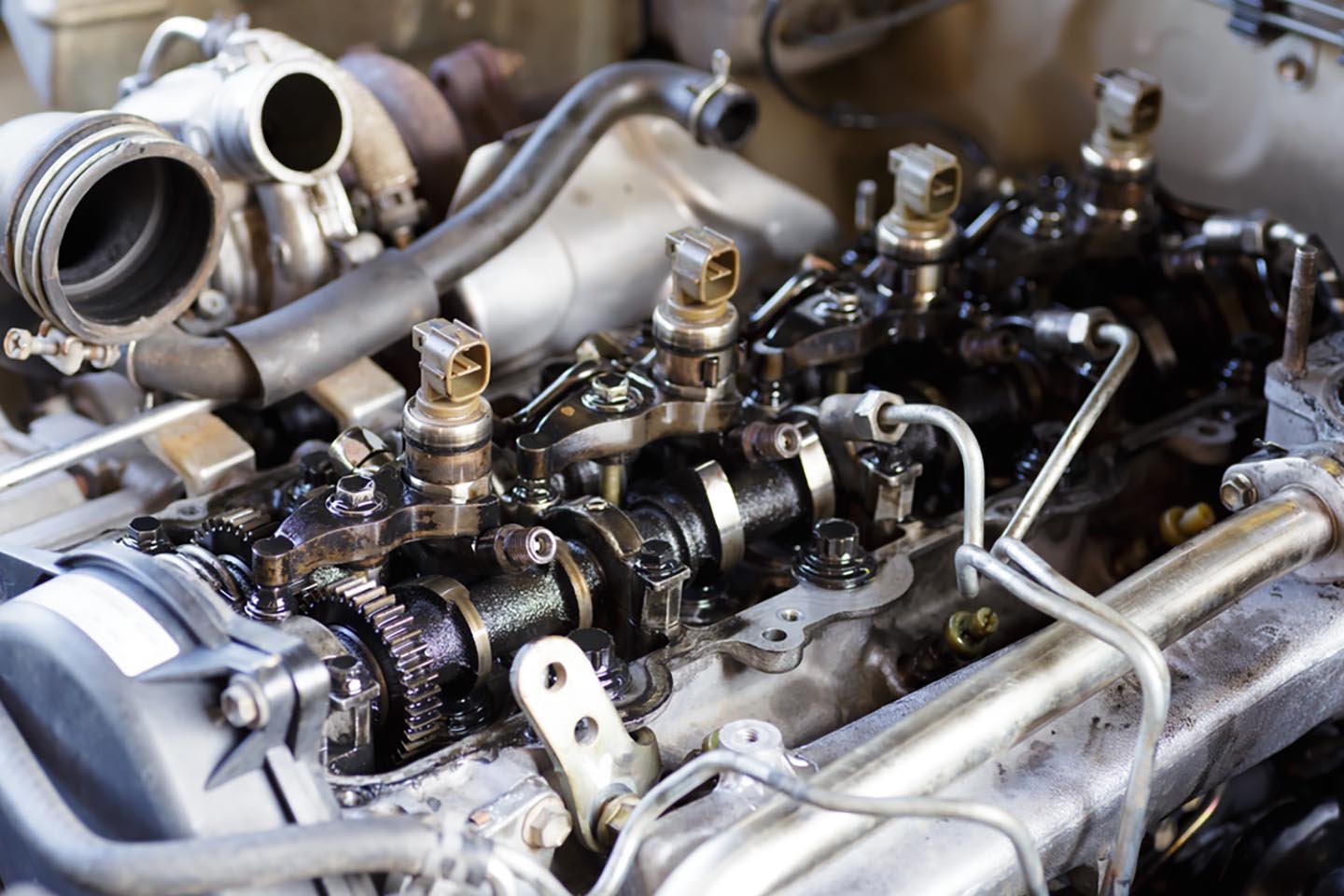

Unlike gas-powered vehicles, diesel engines pressurize fuel using direct fuel injection systems. It’s then sprayed as a fine mist in the combustion chamber, making it easier to burn. This configuration makes diesel more efficient than gas, extracting more power from every drop you put in your tank. It also helps large industrial vehicles and heavy haulers accelerate quickly from rest by generating horsepower at low RPMs.

But with great power comes great responsibility. A lack of oil and poor-quality fuel will damage the fuel system, leading to extensive repairs. If the fuel filter is clogged or one of the parts needs to be replaced, you must depressurize the fuel system before making any adjustments to avoid spraying yourself or your equipment with hot, highly pressurized fuel. Learn how to depressurize a fuel system to get the most out of your diesel engine.

Shop All of Our Diesel Fuel Parts

Why Depressurize a Fuel System?

Rolling up your sleeves and bleeding all the fuel from your diesel truck is like hitting the reset button on your fuel system. It clears the way for you to make necessary repairs for less mess and more peace of mind. Diesel burns much hotter than gasoline, and getting hit with fuel could cause injury that’s why it’s important to be aware and know what color is diesel fuel.

Reasons to depressurize the fuel system include:

- Replacing the fuel filter

- Replacing broken or clogged fuel injectors

- Removing excess water or air from the fuel supply

These issues will impact engine performance, decreasing fuel efficiency, power and acceleration. They can also lead to hard starts, rough idling, smoke from the exhaust manifold and strange pinging noises. Water dilutes your fuel supply and can cause the engine to misfire. The tank should have a water separator that automatically pushes the excess moisture to the bottom. Drain it daily to avoid damaging the fuel system.

Excess air forms in the fuel when there’s not enough in the tank. Tiny air pockets prevent the fuel pump from moving the fuel throughout the engine, leading to harder starts and misfires. To fix the issue, you must bleed the air from your fuel system using the directions in the owner’s manual. Keep the tank full to minimize the amount of air in the injection system. Both incursions can damage various components, including the injection pump, fuel injectors and fuel lines.

pecky_photograph/shutterstock

How to Depressurize a Fuel System

Every diesel model is different. Consult your owner’s manual for model-specific information on how to drain the fuel system.

- Start by shutting off the engine to let it cool. Many models return unburnt fuel to the tank while it’s still hot, so give it time to reach room temperature.

- Loosen the fuel filter cap without removing it to drain any remaining pressure.

- Use your owner’s manual to locate the fuel line fittings, which are usually on the engine compartment or the undercarriage’s frame rail. Use a flare wrench to loosen the fittings without removing them. This releases the pressure inside the fuel line.

- Wait for the hissing to stop and clean up any spilled fuel.

Nor Gal/shutterstock

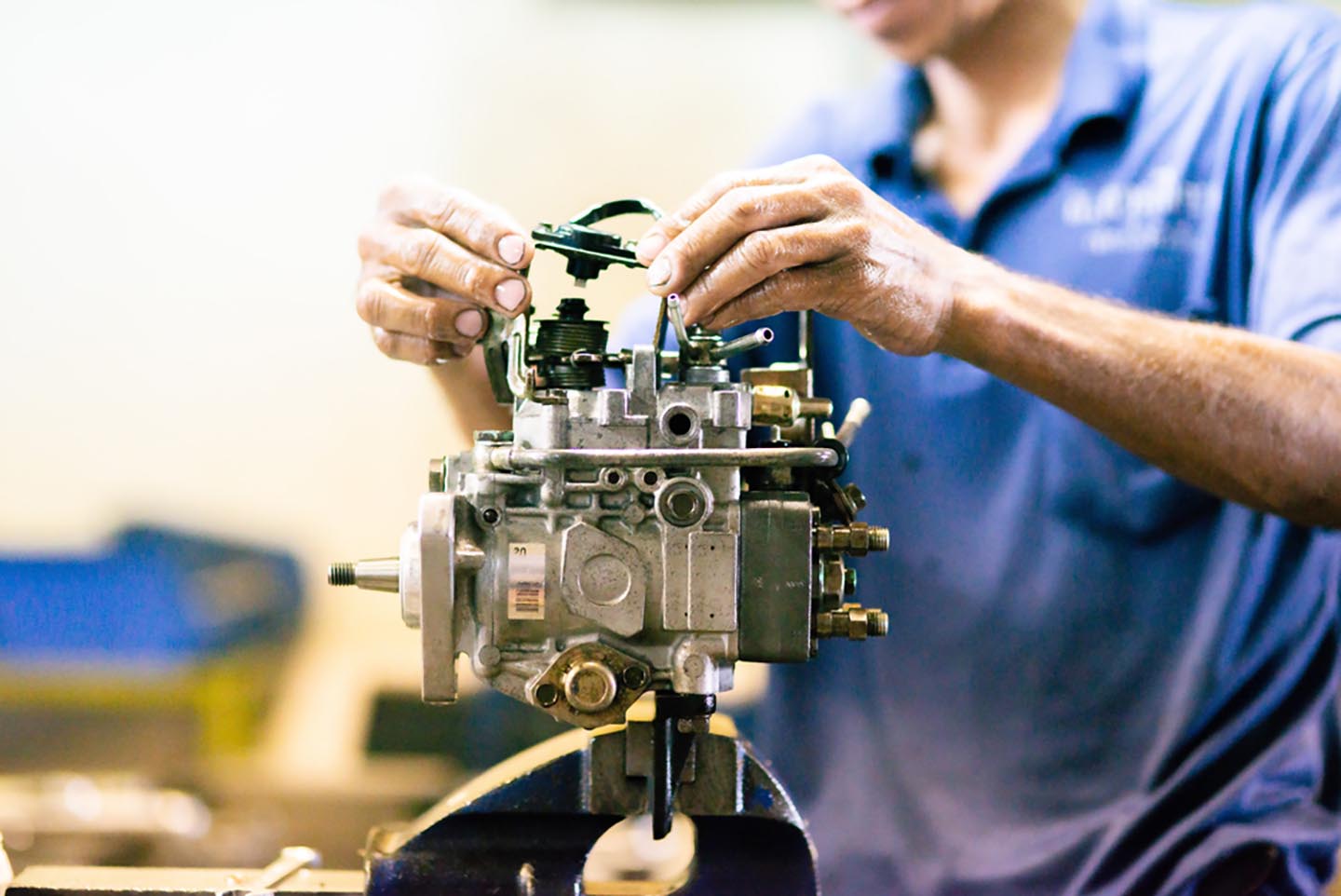

If you’re replacing the fuel filters, remove the fuel lines completely. Diesel fuel filters should be changed every 10,000 to 25,000 miles, depending on driving conditions. Locate the fuel filter and disconnect the sensor’s wire plugs. Open the valve drain to drain any remaining fuel into a pan. Unscrew the filter carriage and raise it straight up, including the o-ring. Follow the filter directions to change out the filter to improve the quality of your fuel.

Inspect the fuel injectors for cracks and sticky carbon that can clog the system. If they appear dirty or damaged, replace them to solve the issue before it saps engine performance. If you’re not getting as much power or mileage out of your fuel even with new injectors, replace the injection pump.

Changing the oil regularly is the best way to protect the injectors. Replace the valve cover gaskets on the cylinder head to prevent oil leaks. Taking your vehicle for longer trips will help the oil move through the system for increased lubrication. Leave the fuel lines unscrewed until you’re done making the necessary repairs. Tighten them once the job is complete, and screw the fuel filter cap back into place.

Diesel trucks are known for pressurizing fuel, but the fuel system needs to be depressurized before making repairs. Use these tips to maintain your injectors, fuel lines and filters like a pro.